Other Parts Discussed in Thread: TPS40428, TPS56720, TPS65400

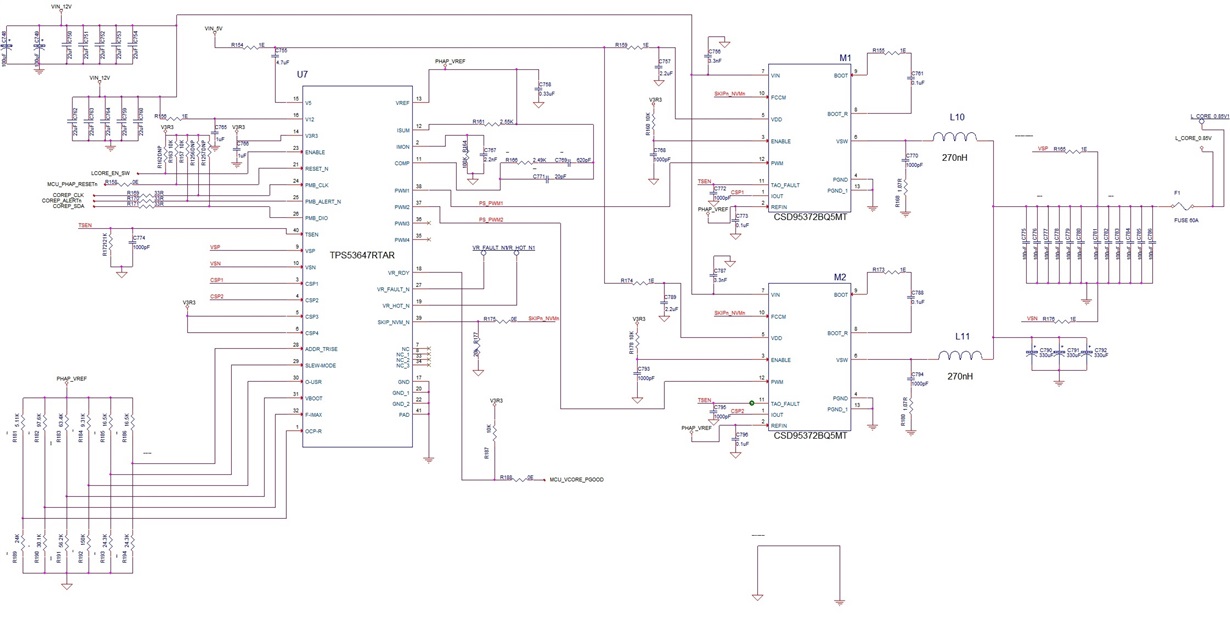

We are planning to use TPS53647 in our application :

VIN = 12V

Vout = 0.8V to 0.9V with 0.85V (nominal)

Current = 50A Max

Programmable through I2C

Output voltage should be programmable

Enable option

I think it supports 120A current with all four phase.

Do i need to use all four phase for 50A current requirement?

Is it compatible with I2C bus interface?