Other Parts Discussed in Thread: TPS3824

Hi team,

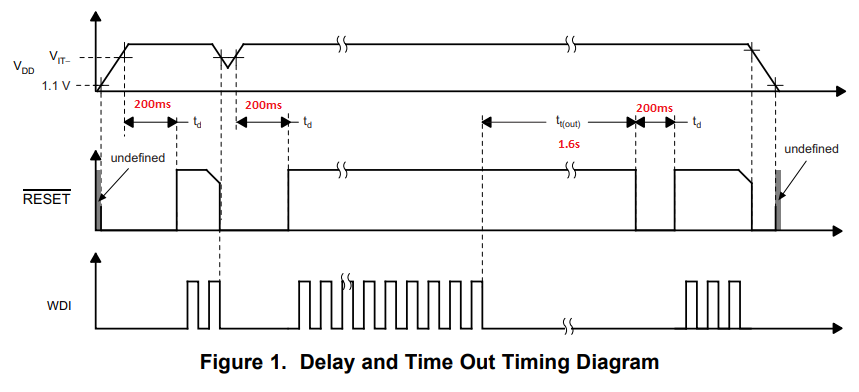

My customer is using our TPS3824-Q1 for their WDI design and they are using our TPS3824-Q1 evm.

They don't get the correctly reset signal after the end of WDI signal. The fail rate is pretty high.

Please refer the pass case and fail case as below figure. May I have your help to understand why there is no reset signal? Thanks.

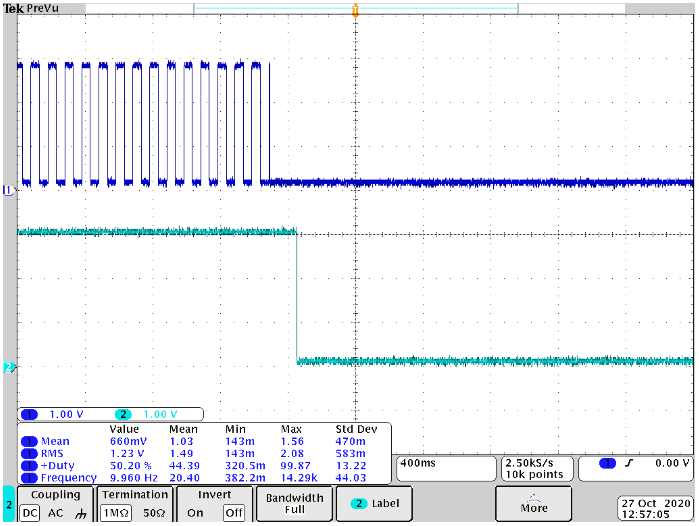

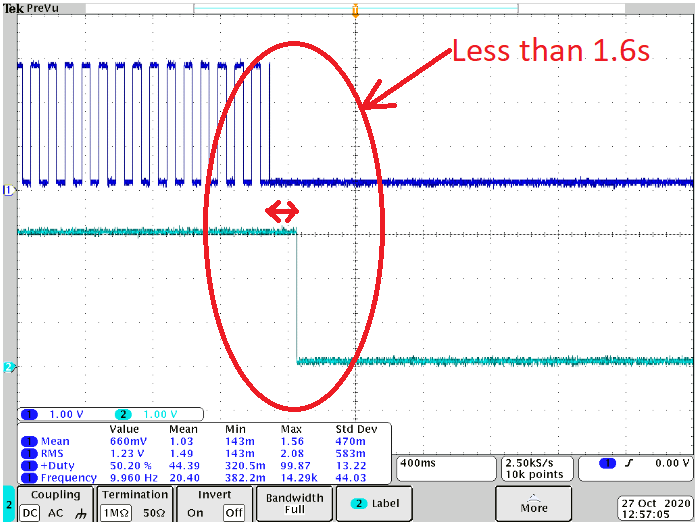

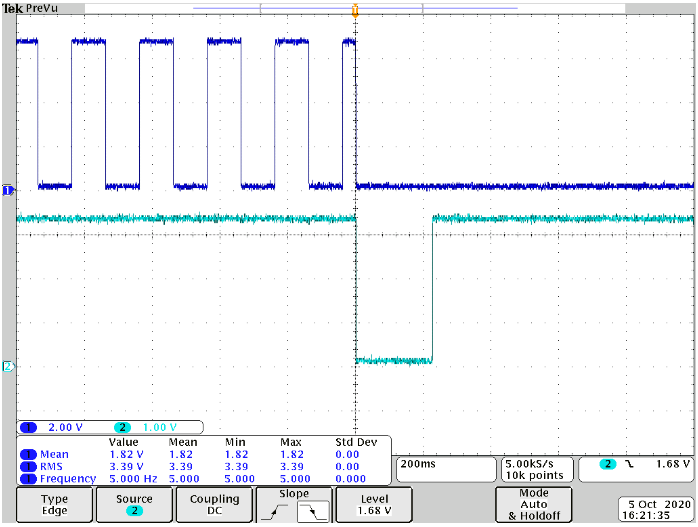

Fail: CH1 WDI, CH2 reset, Reset pin doesn't assert low

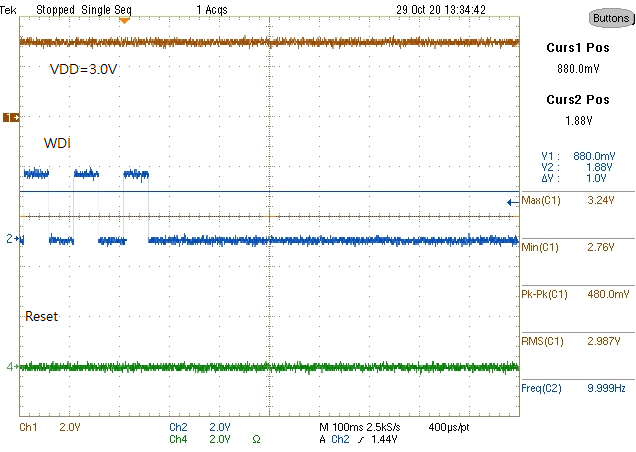

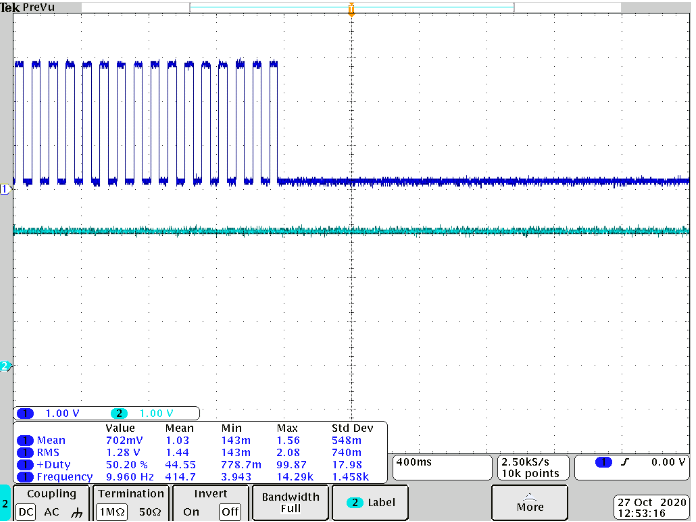

pass: CH1 WDI, CH2 reset, Reset pin assert low