Other Parts Discussed in Thread: BQ78350, BQ78350-R1

Hi

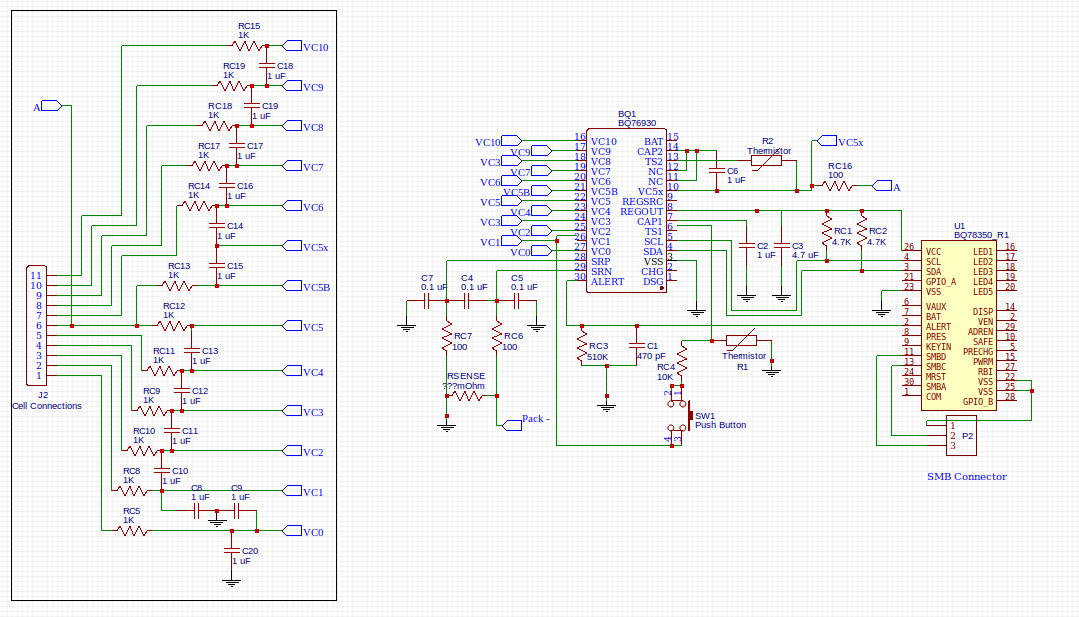

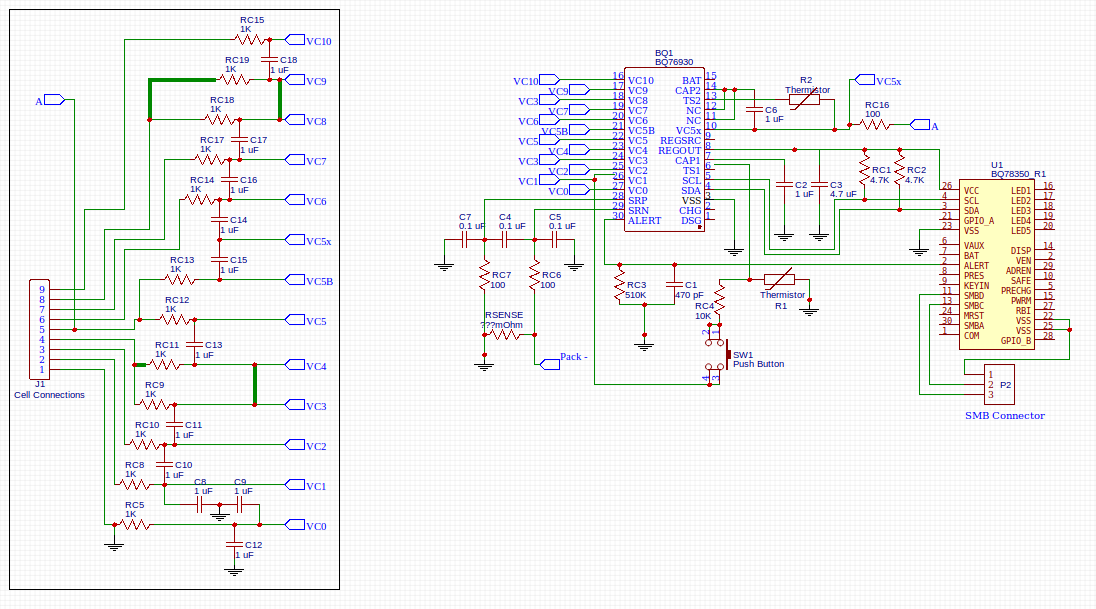

I’ve posted a few times about designing a BMS for a LiFePO4 battery (BQ78350-R1: bqStudio is not showing cell voltages, BQ76930: Design help requested for BQ76930).

I’m now at the stage where I could really use some help with the detailed design. As was suggested during an earlier post on this forum, I went and purchased the BQ76930 Evaluation board (and BQ2400 interface module). After a few false starts, this is now running and I’m able to query and set registers as well as observe the fuel gauge behaviour when the board is connected to my battery pack.

Here are the details of my 8s8p battery pack.

Constructed using Headway 38120 cells which have the following specifications:

-

10C discharge

-

Voltage: 3.2V nominal, 2.5V min, 4.2V max

-

Charging Voltage: 3.65V

-

Cut-off Discharge Voltage: 2.0V

-

Charging Method: CC/CV

-

Maximum Discharge Current (continuous): 100A

-

Maximum Charge Current (continuous): 50A

Using the above values, the 8s8p battery pack has the following characteristics:

-

Voltage: 25.6V nominal, 20V min, 33.6V max

-

Charging Voltage: 29.2V

-

Cut-off Discharge Voltage: 16.0V

-

Charging Method: CC/CV

-

Maximum Discharge Current (continuous): 800A

-

Maximum Charge Current (continuous): 400A

Battery Pack is nominal 24V, 80AH.

The largest current draw will be a starter motor that draws approx. 200A. (4.8KW), so I'm thinking I should design the BMS to handle 300A.

Now that I’m designing my BMS, based on what I have understood from using the evaluation board, I have some questions.

- The BQ76930 documentation states that it contains cell balancing FETs. Why are there balancing FETs on the evaluation board? What should I do wrt the balancing FETS? Use the BQ76930 ‘internal’ ones, or should I include ‘external’ FETs in my design?

The one (only?) reason I can see for using external FETs is to increase the balancing current – the internal FETs are relatively limited in how much current they can shift from cell to cell - What about the current sensing resistor? As I’m designing a board that will handle up to 300A, I assume I’ll need to

a) use a suitably large resistor (small R but big W)

b) do some calibration of the gauge so that it matches the actual current being measured. - Is there anything else that I should be thinking about at this point.

Cheers,

Mike