Can anyone comment on whether I can use LDC inductive technology for implementing touch buttons on a non-conductive surface?

Which device can be recommended ?

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Can anyone comment on whether I can use LDC inductive technology for implementing touch buttons on a non-conductive surface?

Which device can be recommended ?

Carsten, real good question. Please refer to the article below which should address your questions. Please let us know if you have any follow up questions. Thanks

Position Sensors and User Interface design - Part I

User interface or human machine interface (HMI) are continuously evolving with advent of technology from a user experience and convenience perspective in most products whether it is the center console of a car, a major appliance like washing machine or a personal device like headsets. Mechanical buttons and knobs are being replaced by seamless touch on surface buttons and multi directional joysticks.

The latest three dimensional (3D) magnetic hall sensors and the contactless inductive sensors from Texas Instruments are ideal sensing technologies to implement these innovative user interface features in today's products. They are easy to integrate and implement and not only improve the aesthetics of the products, they also save cost and reduce wear and tear associated with mechanical buttons and knobs. Overall a clean look with robust operation and protection against environmental damage.

Seamless water proof touch buttons with LDC inductive sensors

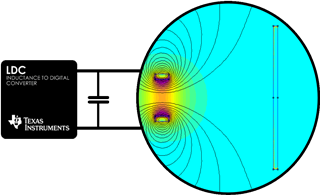

The LDC family of inductance to digital converters are signal conditioning ICs that measure the change in resonance of a inductive coil laid out on a PCB when a conductive target approaches or moves away from the coil (Figure 1). These sensors can be used to measure the small deflections in the conductive material as a button touch or as a precise linear sensor for proximity sensing.

Figure 1: LDC sensor IC connected to an LC tank circuit (L implemented as a coil on PCB) with a moving target

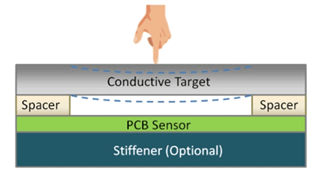

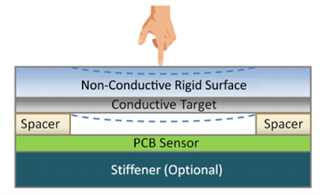

The LDC family of devices can be designed to enable touch buttons on conductive surfaces (Figure 2) like copper, aluminum or steel as well as on acrylic plastic or glass surfaces with the addition of a conductive layer to the non-conductive material (Figure 3). On top of touch on surface, product designers can incorporate force touch function on the same button with it's ability to detect the difference in force applied on the surface/button. This capability can enable additional features like selecting from pop-up menus on displays or to implement a secondary function on the same button.

Figure 2: Touch button structure with conductive surface Figure 3: Touch button structure with non-conductive surface

In addition, some of the inductive sensors (LDC2114 and LDC3114-Q1) incorporate a baseline tracking algorithm feature to automatically compensate for any slow change in the sensor output caused by environmental variations, such as temperature drift or wear and tear of the surface material over time. The user benefit of this feature is to prevent false touch due to de-formation of surface material or temperature changes.

Some of the key benefits of touch buttons, sliders or knobs implemented using inductive sensors are:

In addition to user interface buttons, position sensors can be used to design knobs and joysticks which will be discussed in a subsequent article.

Get started with TI’s inductive sensors

No matter what type of user interface or HMI you are designing, TI has the right inductive sensor for your design – the LDC3114-Q1, an automotive 4-channel inductance to digital converter for low-power proximity & touch-button sensing.

Additional Resources

Inductive sensing requires a conductive target to sense movement. With careful construction, you can use a conductive target that is just a metal plating as thin as 15um on the bottom side of the touch surface - 1/2 oz copper or even aluminum foil can function as a target - simply adhere it the inside surface.

Thank you Chris. you are correct on the need for a conductive layer as target attached to the non-conductive surface.