Other Parts Discussed in Thread: FDC1004, TINA-TI

Hi team,

Here's an issue from the customer may need your help:

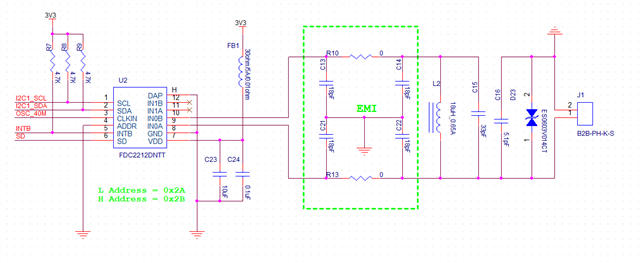

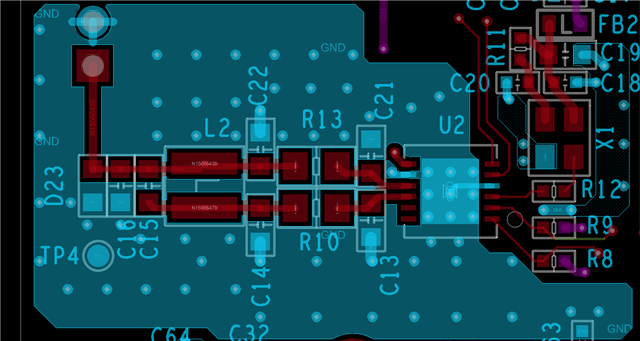

Signals captured in the 80 to 200 MHz band are subject to interference and cannot be used. According to the demo board manual, two capacitors close to the chip pins can be adjusted for interference immunity:

1) Is it required to adjust the values of the 4 capacitors together when adjusting the capacitors?

2) Regarding the above frequency band, is it required to be adjusted up or down from the original 18 pF? And are there recommended values?

Could you help check this case? Thanks.

Best Regards,

Cherry