Other Parts Discussed in Thread: HDC2021, HDC2080, HDC2022, MSP-EXP430F5529LP, ENERGIA, BP-BASSENSORSMKII, TMP117

Hi,

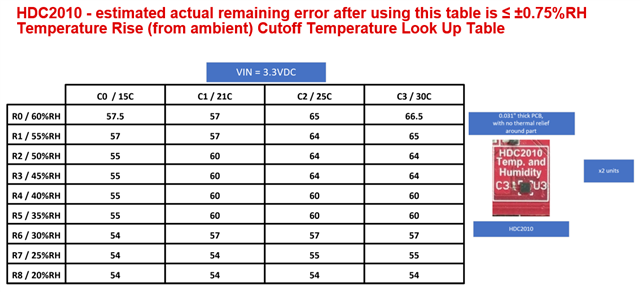

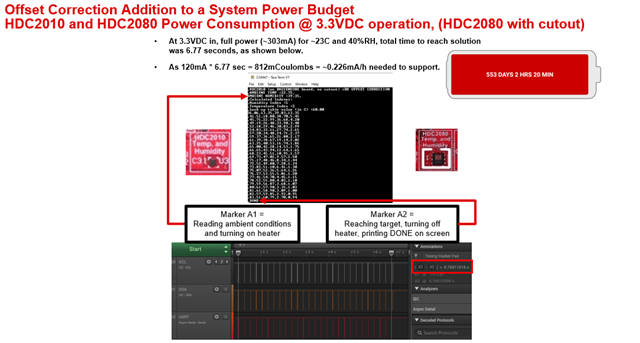

I have been maintaining an IOT environmental sensor which features the HDC2010 sensor. We have been observing a positive humidity offset in these devices - the how and why of the offset is well documented in other forum posts. In-field calibration is not an option, and their environment cannot be well controlled. I am considering migrating to the HDC30xx series for future designs, but we already have thousands of pieces of hardware already manufactured.

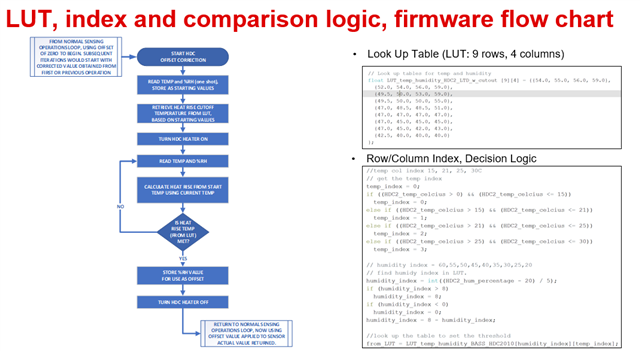

My question was whether the "Offset error correction" procedure shown in the HDC3 Silicon users guide could be applied to the HDC2010? The HDC2010 also has a heater - so I don't see why the same theory could not be applied.

If so, would there be any differences in the procedure, and how would I acquire the correct lookup table? Are TI able to provide one, or provide the methodology for generating one?

Any comment would be appreciated.

Cheers,

Tim Lamborn.