Other Parts Discussed in Thread: TMP117

Hi,

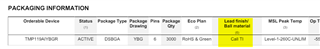

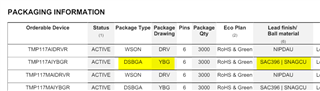

I need to implement a temperature sensing solution where TMP119 would be located on a needle PCB (ultra narrow) to get a quick and accurate measure.

I would like to know how to implement this.

PCB would be within a needle (kitchen like temperature sensor, PCB within needle with thermal coumpound

We need to use BGA for the "needle side, but we would like to know how to implement this.

Where is the sensing, what shall be implement

- Exposed copper (but connected to which IO?)

- No soldermask?

...

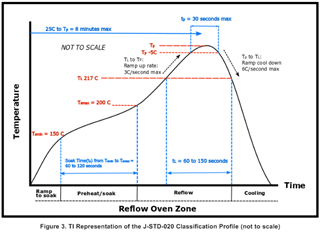

Also, the component is given for 150°C, but what is max temperature for BGA balls? Is there a risk of unsoldering due to melting point reach? What is the max temperature under permanent conditions?!

Thanks

BR