Tool/software:

Hello, it is me again.

Since this forum was so helpful the last time, I thought I'd try again!

First off, I've seen and read the following threads already:

- https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/1249795/ldc1614-temporal-drift-of-the-absolute-value

- https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/1134089/ldc1614-inductance-value-increased-with-time

- https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/813689/ldc1614-q1-output-drift

- https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/546430/ldc1614-warmup-drift

On to our problem:

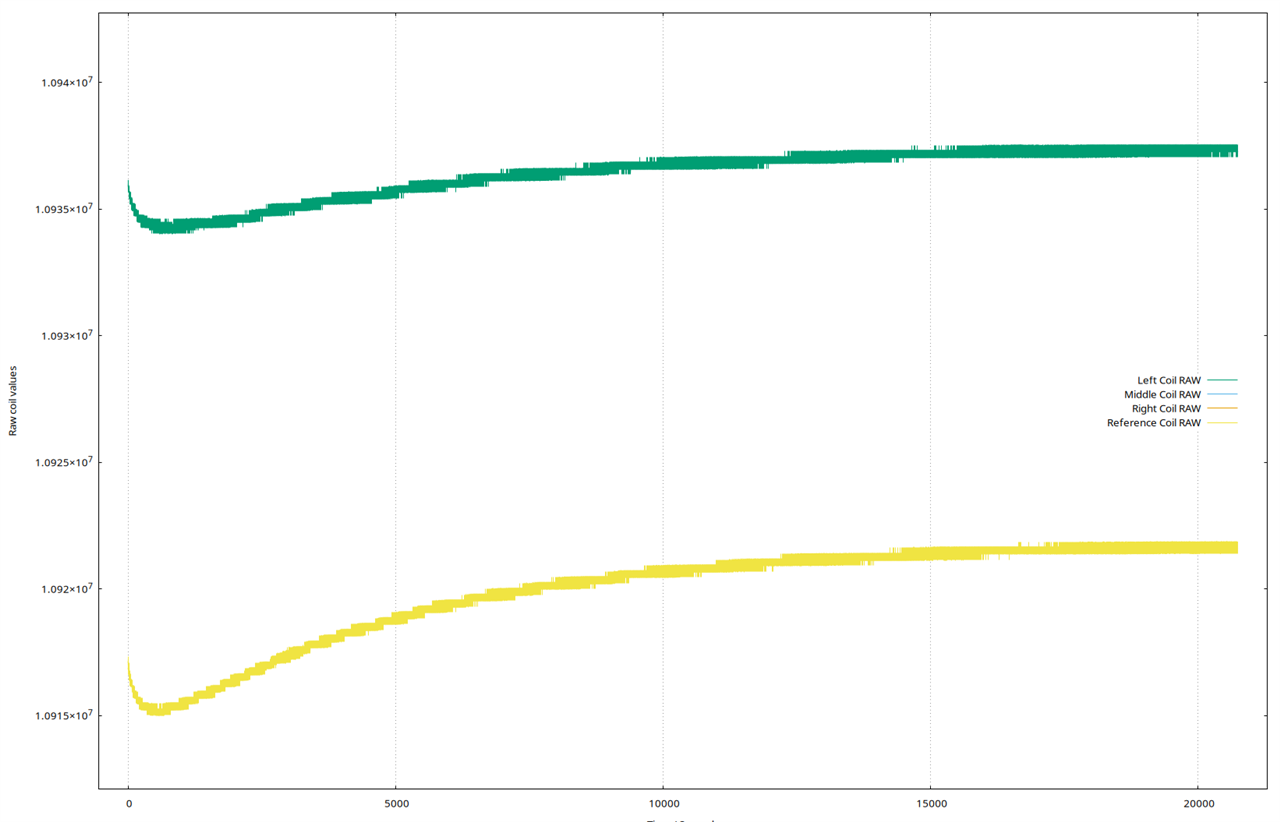

The measurement, as was described here (https://e2e.ti.com/support/sensors-group/sensors/f/sensors-forum/1443373/ldc1614-wrap-around-noise) works pretty well indeed. We have one remaining problem: a drift over time. At first we used a pretty cheap LDO that was not temperature stable (3.21V to 3.29V from 0°C to 100°C). We replaced them with the TI TLV1117LV33DCYR which seem really stable (only 0.5mV deviation from 25°C to 100°C). However, the problem only marginally improved. As seen in the following plots, the counts first drop and then increase again (measurement time: 5:40h, no changes in the setup during that time, room temperature was stable as well):

Here's also a zoomed and normalized view:

We do use NP0 capacitors for our four coils. Baseline compensation is hard since left, middle and right are engaged at all times and the measured metal rod changes. The ref coil is independent of these changes, but its drift is also a bit different. Moreover, the clock is temperature compensated as well.

We're now at a point where we don't see any way of improving our results besides improving the SNR (which we will do, later). Is this drift expected? We assumed the setup would be more stable than what we observer right now. Is the drift something that happens in the LDC? Because I'm pretty sure we can be sure that both the LDO and the clock are stable.

Thank you for any comments!