Other Parts Discussed in Thread: LDC1314

on some parts I observe sporadic outliers on one ore more DATA_CHx channels.

The value for DATA_CHx then jumps to 4095 for 1 sample while before and afterwards the values are ok.

There are parts not showing any issues, other where 1 channel is affected and I have also seen a part with 2 channels showing this.

The system is operating at room temperature with the object in the normal detection range.

The deglitch filter is set correctly to the lowest value above the resonant frequency.

The amplitude has been checked and is within the expected range.

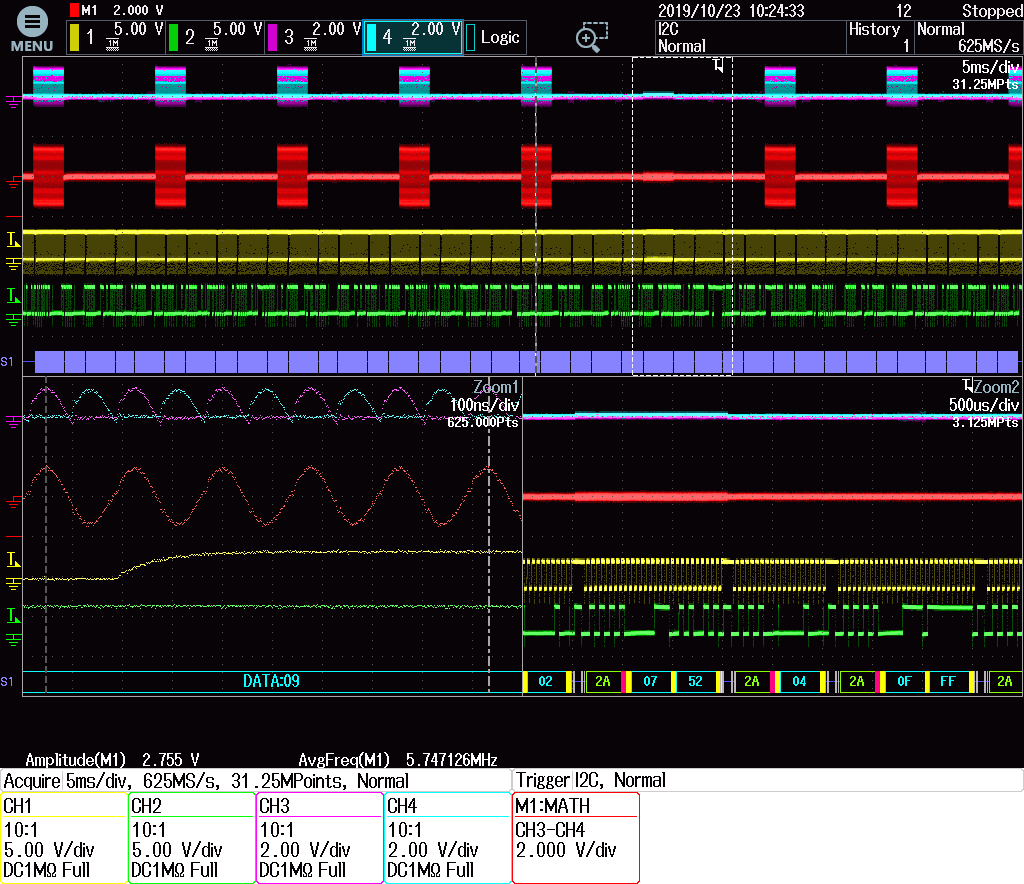

The scope plot illustrates the issue:

Trigger is activated when DATA_CH0 = 0x0FFF (4095) is transmitted. (zoomed portion lower right side)

You can also see that the measurement before this transmission didn't happen correctly.

CH3 / CH4 are probing the CH0_A / CH0_B and M1 is the calculated difference.

In the zoomed picture left right you can see the normal amplitude in one of the successful measurements before.

Any ideas what this issue could be caused by?

best regards,

Martin