Dear Sir/ Madam,

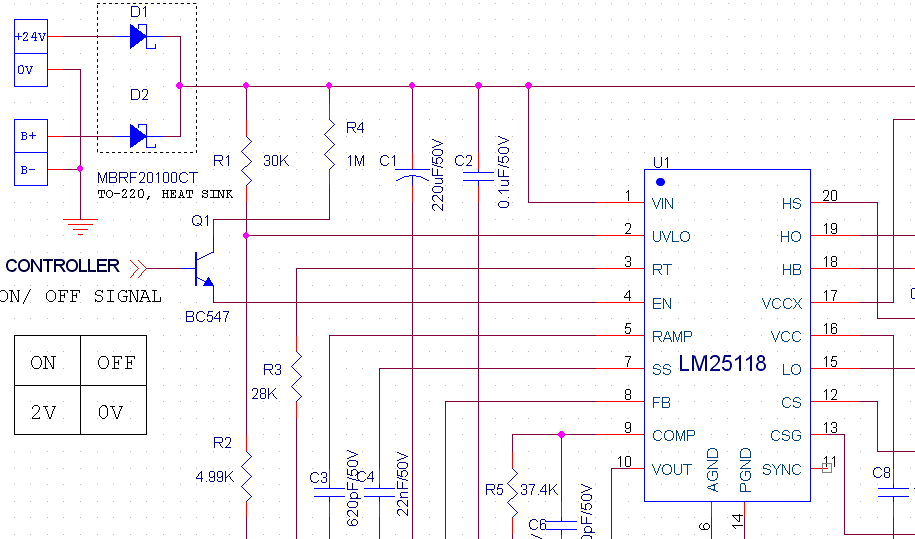

We selected Non isolated DC-DC BUCK-BOOST converter LM25118 for the required specification mentioned,

Input voltage range - 10.8 - 28 VDC

Output voltage - 12 VDC

Output current - 4A

We designed using WEBENCH DESIGN TOOL by changing some components and extract the schematic file and also board layout file of Altium but we doesnot find the gerber file in the board layout document. We kindly request you to guide us the procedure to obtain the gerber file.

with thanks and regards,

Mohan Kumar K

Nandipowertronics Pvt Ltd.,

Bangalore - 5600079

Mob - 09986000128