Other Parts Discussed in Thread: CC2650

Good morning,

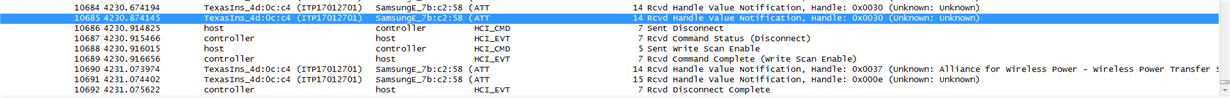

We are using the CC2640 for our project since a year now and we have sometime an issue I can't find the origin.

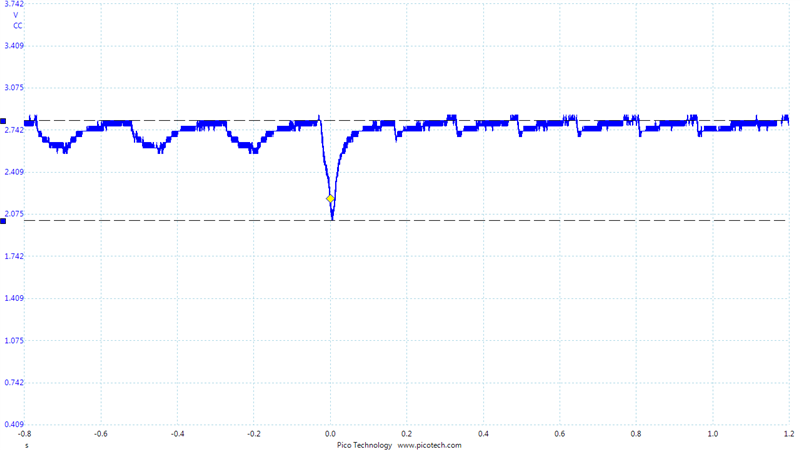

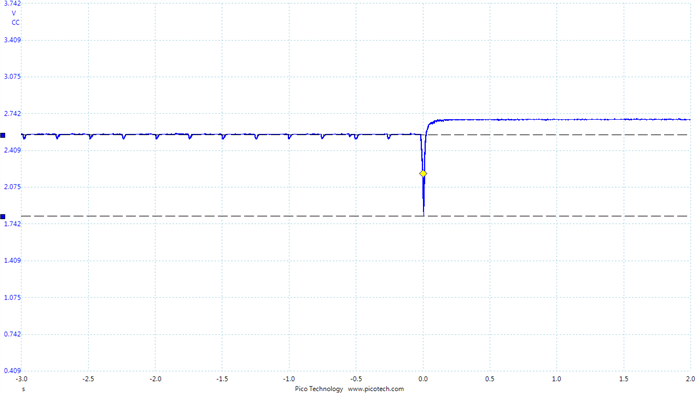

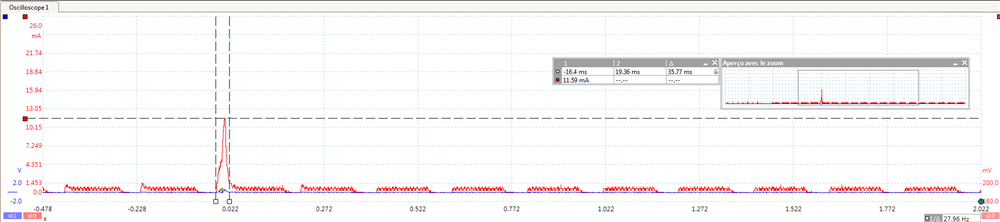

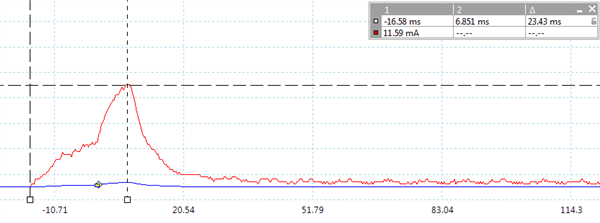

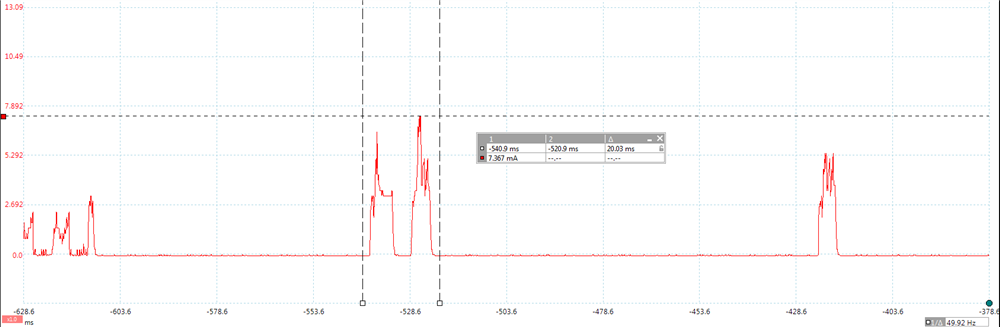

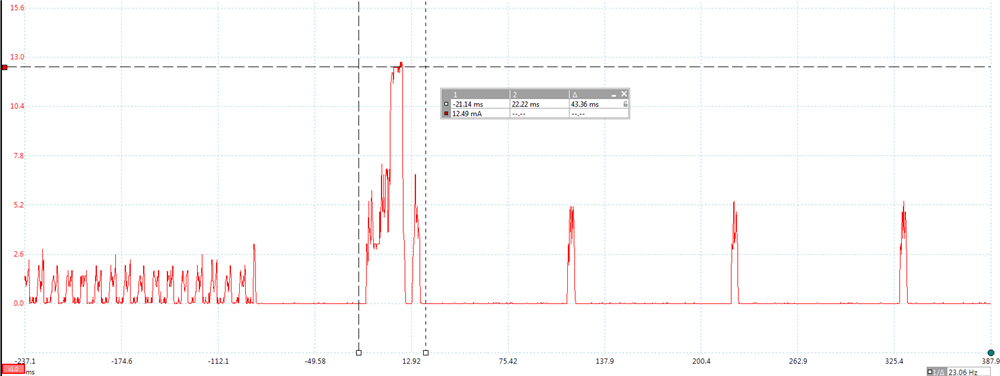

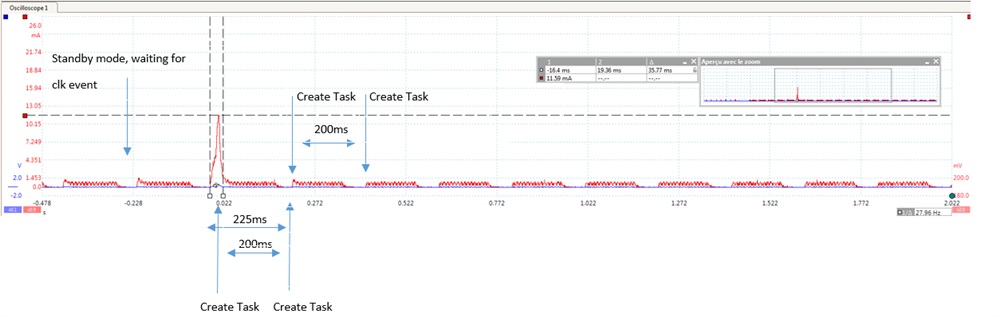

After a few days, the Advertising seems to be disabled, and voltage on VDDR pin and DCOUP pin are down to zero. As far as I know, the only way to get to this state is by decreasing the global voltage power to ~1.7V while the system is working. We use a CR1616 battery and 2x47uF tantalum capacitors on the VDDS pins, everything else is like on the reference design.

Is there any other possibility (like a software issue) that can lead to this state ? Is it possible to prevent the system or trigger this voltage ?

Thanks in advance