rt Number: CC2650

Tool/software: Code Composer Studio

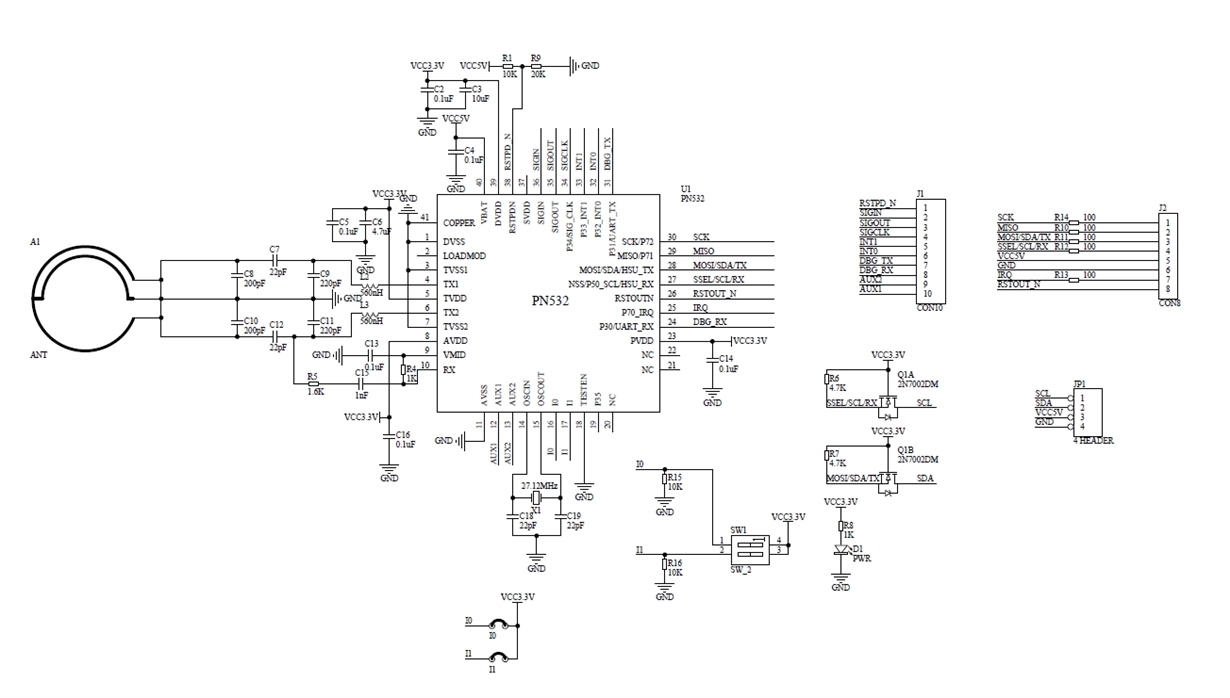

I have a need to do I2C communications with an existing Elechouse RFID reader module that uses an NXP PN532.

After reading the 530 pages of PN532 datasheet, user manual, application note and Elechouse PN532 NFC RFID Module User Guide Version 3, I failed miserably to even get a response from the PN532 module.

I then resorted to grabbing an Arduino Nano I had kicking around and used Elechouse Arduino library examples to get the module to successfully read my Mifare 1k tag's Uid.

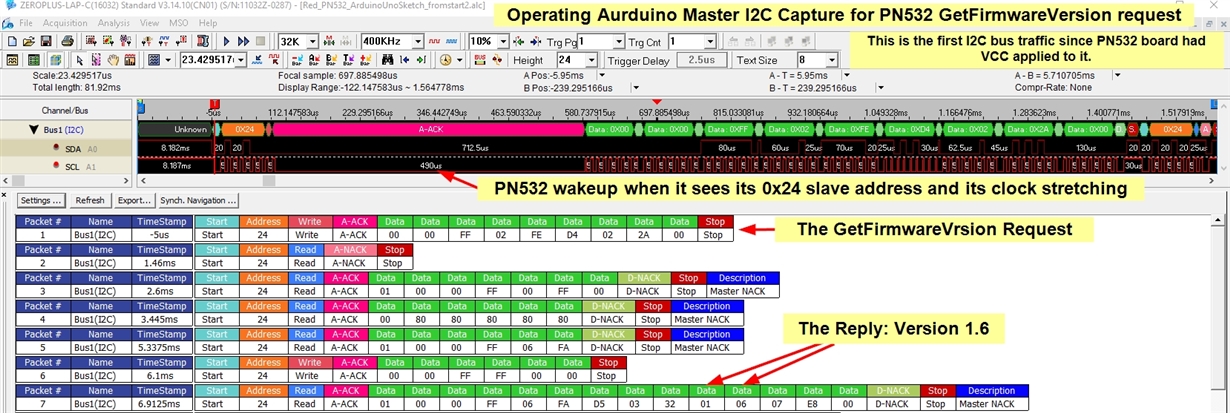

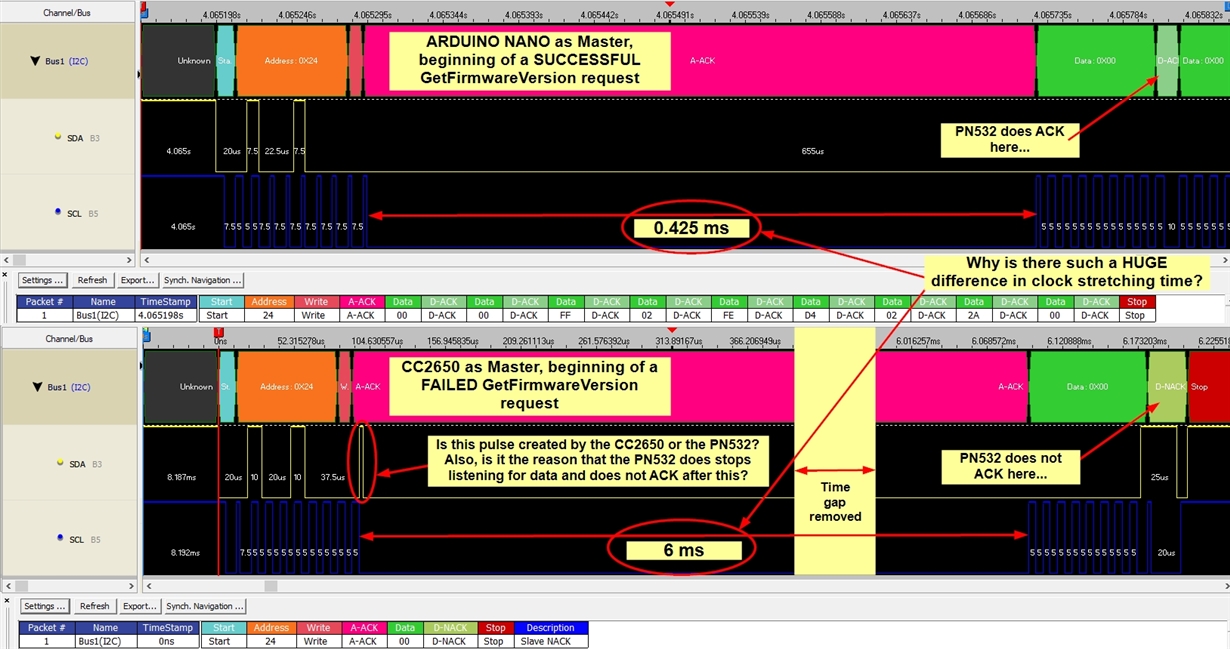

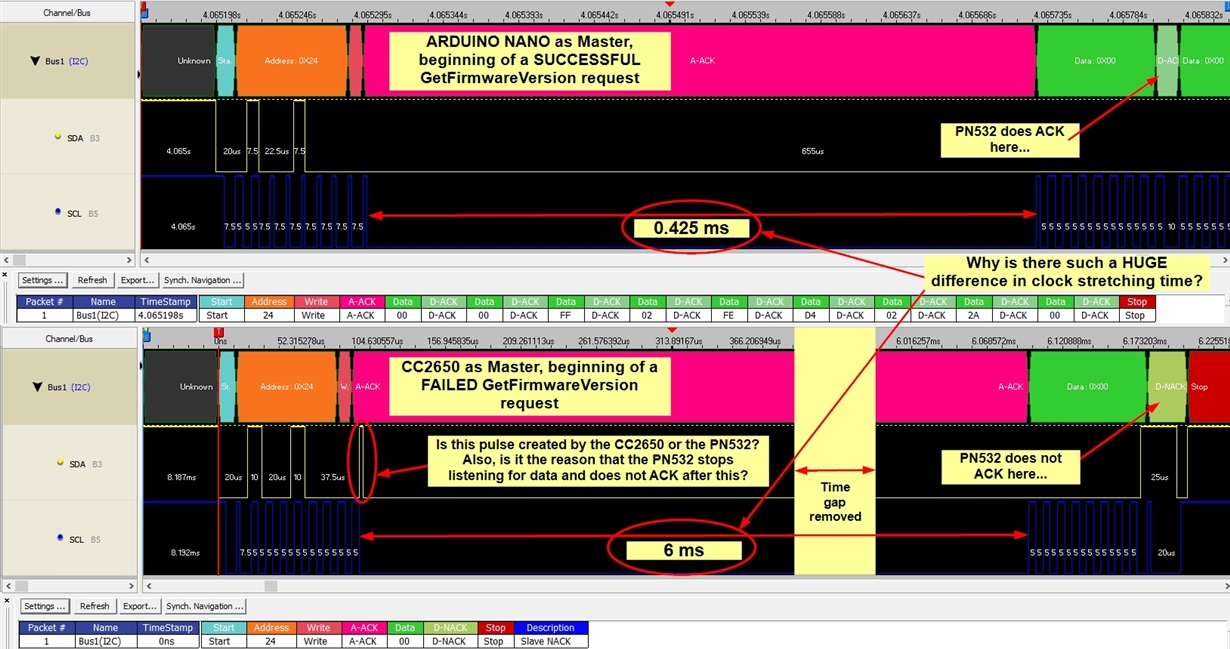

I then used my Logic analyzer to capture the I2C bus traffic when the Arduino sketch started up.

That gives me a map of what I2C commands I need to mirror in my 'CC2650 as master' code and here is the first command and response that 'Arduino as master' does after the PN532 has power applied to it. (GetFirmWareVersion):

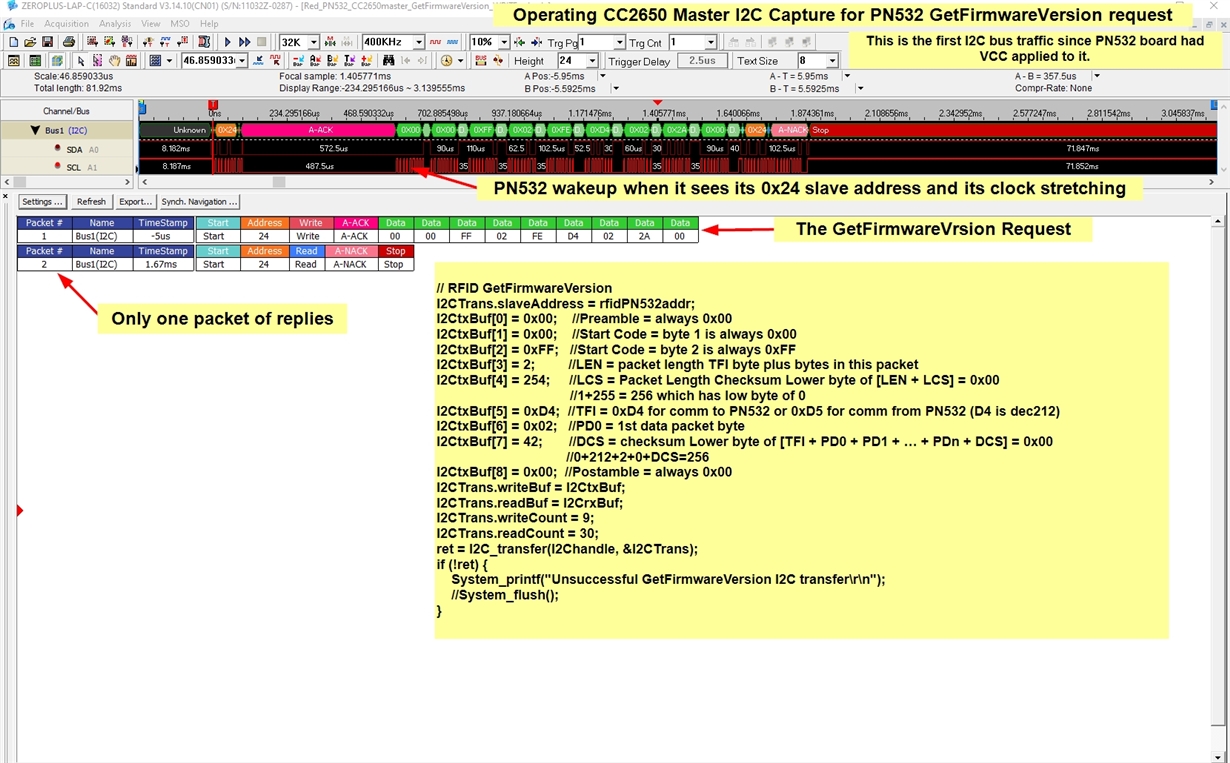

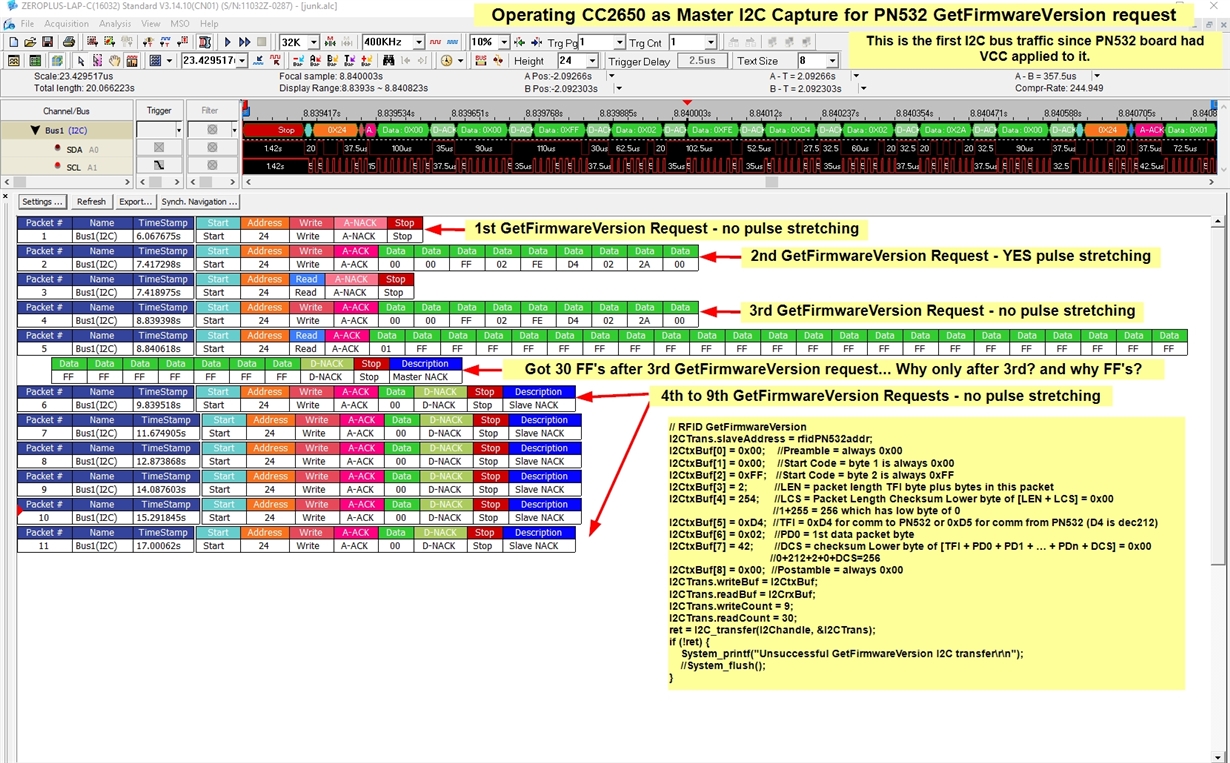

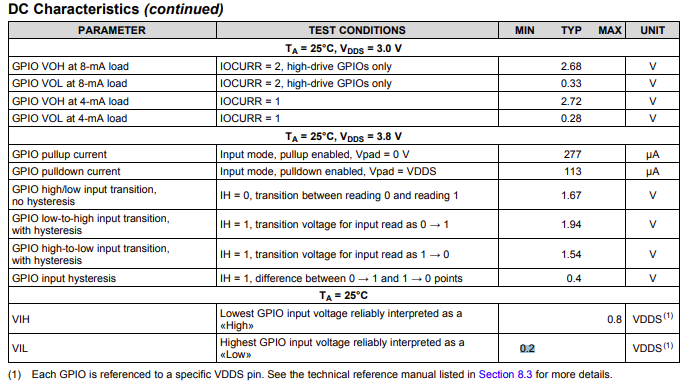

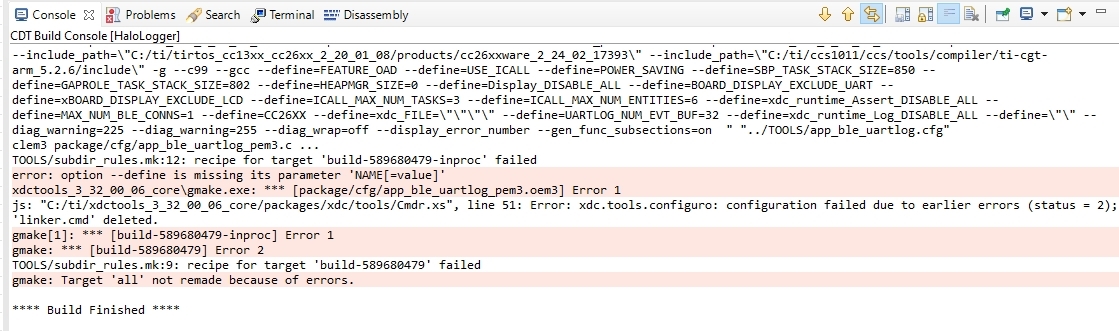

Then, I tried to match that communication traffic with the CC2650 and I could only get this far (my code is in the image):

So, the only thing I have accomplished so far is to wakeup the PN532 by sending its slave address of 0x24 on the I2C bus and then it clock stretches while it stretches its legs I guess ;).

I can not figure out how to read its full response to my GetFirmwareVersion request like the Arduino is able to.

Can anyone give me some guidance on how to obtain the complete set of responses to my GetFirmwareVersion request with 'CC2650 as master' that 'Arduino as master' is getting from the PN532 module?

Once I can get the full responses to this request, I am pretty sure that I can continue form there to completion of my code.

And, by the way, my I2C_transfer command fails because I get my console message of "Unsuccessful GetFirmwareVersion I2C transfer".

Thanks,

Dale