Battery packs are used in the products that we depend on daily. Many of our portable devices such as our cell phones, our watches and our tablet computers are constantly at our sides and running on batteries. Consequently, their batteries discharge throughout the day and we have to recharge them every one to two days. We assume that the gauges in these products are accurate and will not leave us stranded between charges. Fortunately, gauges do monitor our batteries accurately and maintain this accuracy by updating the available capacity of the cells as they age. These updates do require that the cell discharge periodically and the depth of the discharge depends on the type of gauge.

Impedance track gauges require at least a 37% discharge and CEDV gauges require almost a full discharge. While this is not a problem on products that we take with us, there are products where discharges are not common and maybe not even allowed. These are referred to as rarely discharged applications and some examples are backup systems, emergency battery power modules and portable computers that you leave plugged in at your desks. Backup systems must maintain a high state-of-charge to be available should a power failure occur. You cannot risk a full discharge or even a 37% discharge and still have enough capacity available for a system backup in most cases.

Figure 1: CEDV learning profile vs. supporting a backup (a); EOS learning profile vs. supporting a backup (b)

The challenge is how to detect that the battery is aging without compromising the capability to support a backup event. TI has developed the new end-of-service (EOS) algorithm to provide an early warning that the pack has lost its ability to support a backup. This algorithm only requires a shallow 1% to 2% discharge to measure the series resistance of the cells. This discharge can occur from the present voltage state or you can charge the pack and then initiate the discharge back down to the current state.

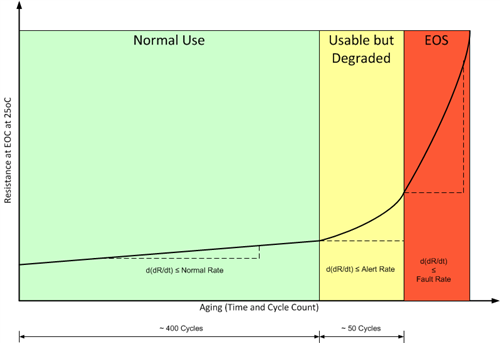

The gauge uses a special filtering algorithm to analyze the series resistance during this “learning phase” and it monitors that resistance over time to detect when it starts increasing significantly. The increase in the series resistance is an indicator that the cells have degraded and may not longer be able to support the backup. The gauge will provide an EOS flag to the host when it determines that the cells need to be replaced.

Figure 2: Series resistance aging detected by the EOS algorithm

The bq34110 incorporates the EOS and the CEDV algorithms to provide a full suite of gauging options for the pack. The CEDV algorithm updates the gauging accuracy of the discharge as the cells age. The EOS algorithm (Figure 2) warns the host that the cells need to be replaced, if discharges are not possible to keep the available capacity updated. The device also provides a “learning load” control output to allow the gauge to control the load required to support EOS learning. The gauge will also update the Full Charge Capacity for the CEDV algorithm when a full discharge occurs to provide accurate State-of-Charge estimates for normal discharges. The gauge supports Li-Ion, LiFePO4, Lead Acid and Nickel Metal Hydride (NiMH) cell chemistries and cell stacks up to 65V. If your design does not allow periodic discharge events, then the EOS option may be a good option to know when the cells need to be replaced. The algorithm supports most of the rechargeable battery chemistries and it also supports Lithium primary cells. More information and samples are available on the bq34110 and bq35100 product pages.

Additional resources:

- Learn more about designing with battery fuel gauges with these blog posts:

- Watch the training video: Unique Gauging Algorithms for Industrial Applications - Primary Cells & Rarely Discharged Applications

- For more information on gauging please visit www.ti.com/gauge.

-

Harmeet Singh

-

Cancel

-

Up

0

Down

-

-

Reply

-

More

-

Cancel

Comment-

Harmeet Singh

-

Cancel

-

Up

0

Down

-

-

Reply

-

More

-

Cancel

Children