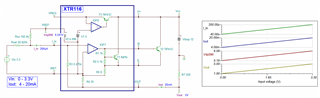

Part Number: XTR116

Other Parts Discussed in Thread: XTR117, XTR111, XTR115

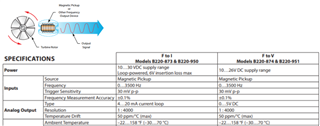

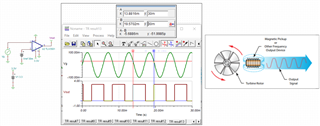

I have a turbine flow meter to measure 0-250 gallons per minute of diesel pumped through filtration. The $415 Instrumart F to I converter failed new, They want $700 to test it, or $560 to replace it. I want to build a new F to I converter using the XTR116 for output. The turbine flow meter has a propeller in a 3" tube with magnets. A proximity detector reads the magnets and creates a sine wave corresponding to flow. It has a K-Factor that shows the calibration as 52.993 pulses per gallon. At full speed 250gpm * 52.993 ppg / 60 sec per minute is 220 Hz should output 20mA, 0 Hz should output 4mA, 200 gpm is around 177 Hz, 100 gpm is 88 Hz.linear scale.

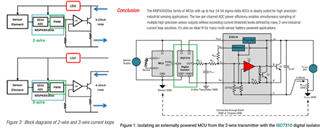

The XTR116 looks perfect for the output, I downloaded the "tiduao7" 2-wire 4-20mA Transmitter reference disign from the TI website. I am looking for suggestion for the front end zero crossing detector for the proximity detector at 30 mV or better, and a micro controller to to the math and output to the XTR116.

Could you please recommend a micro controller for the front end? The entire system of course must consume less than 4mA. Would a MSP430F20xx work for this. The XTR11x has a loop powered 5v regulator, so it would be better to find a microcontroller that operates a 5v that has an analog input to detect the proximity detector in the turbine flow meter.

Thank you,

Robert