Hi all,

My customer would like to know solder heat resistance of DIP package.

I found the solder profile application report, but there is no mention of preheating or peak temperature.

Recommended Soldering Profiles (Rev. J) (ti.com)

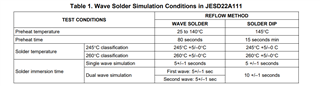

Isn't there a report with flow conditions like SMT package? (see below)

Wave Solder Exposure of SMT Packages (ti.com)

I would appreciate it if you could tell me.

Best Regards,

Ryusuke