Tool/software:

Hi,

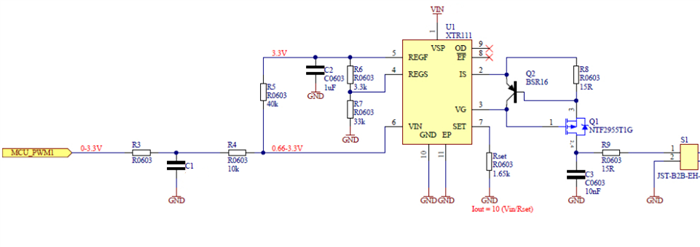

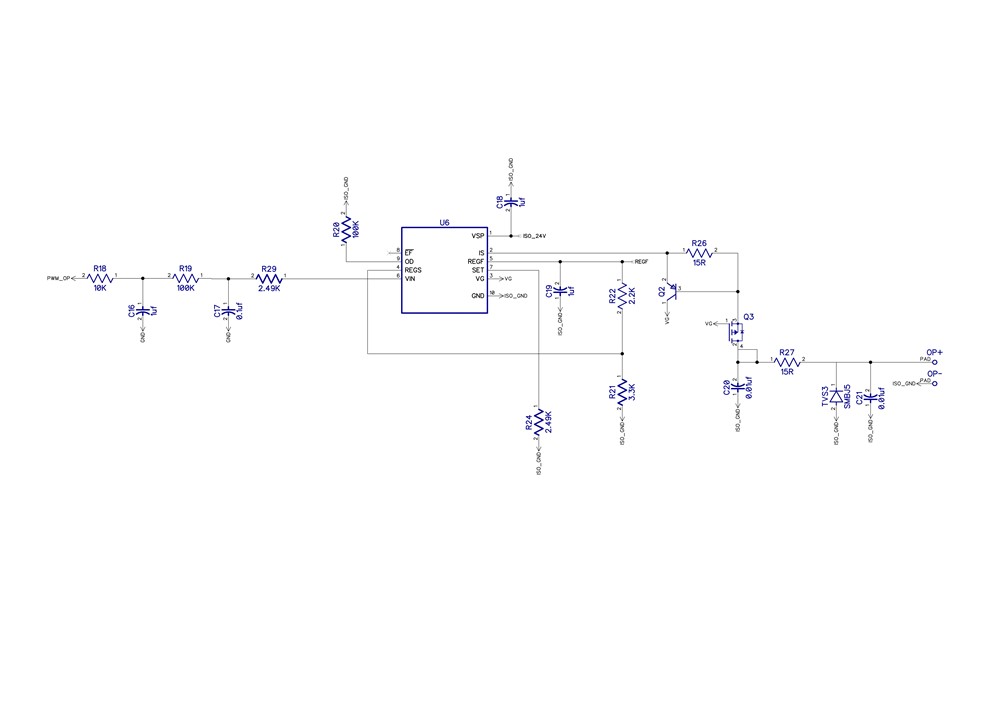

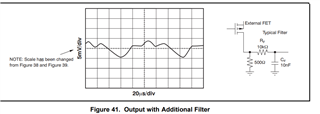

My controller don't have DAC i am using a PWM output for the 4 to 20 mA output, Now i want to use XTR111 for the 4 to 20 mA.

So is it possible without DAC using PWM may I generate 4 to 20 mA using XTR111 ?

If you have document pls provide.