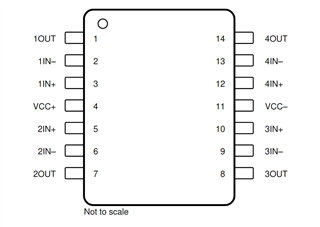

Part Number: TL074H

Other Parts Discussed in Thread: TL074

Tool/software:

Team,

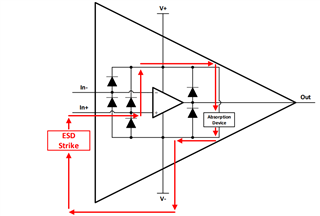

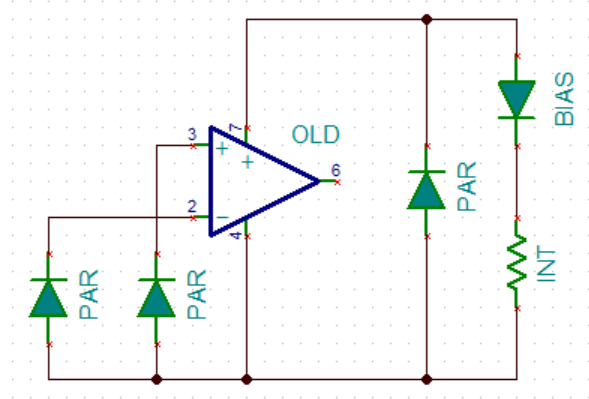

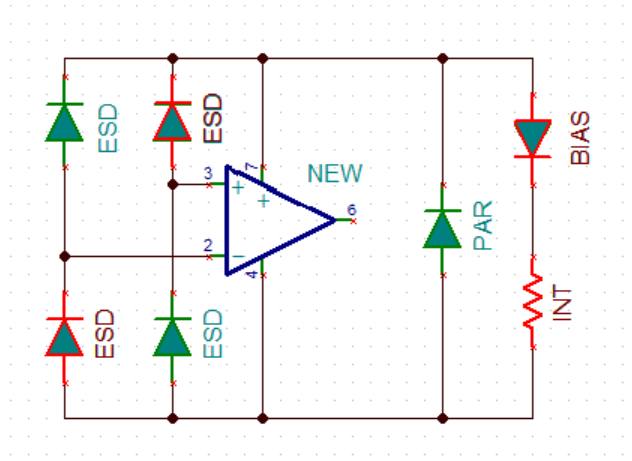

I'd like to know what is the topology of the ESD diode inside the TL074H. Customer plans to do the ICT(Initial circuit test) test at ESD diode in the production line. Is below diagram identical to TL074H? Or what else diagram you can share? very thanks.