Other Parts Discussed in Thread: OPA192

Tool/software:

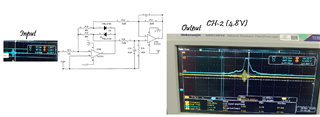

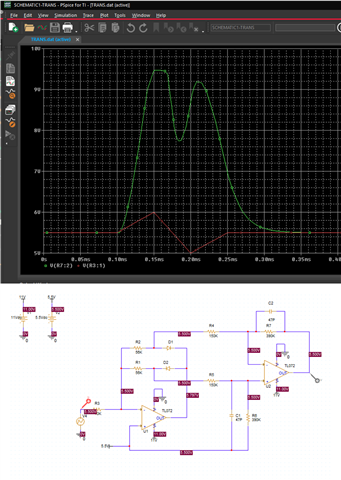

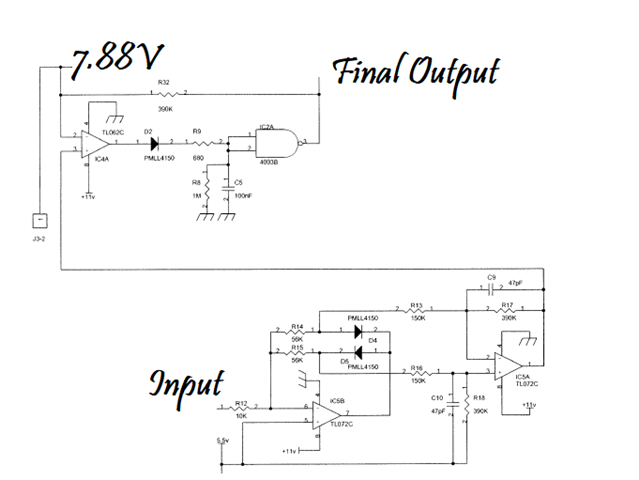

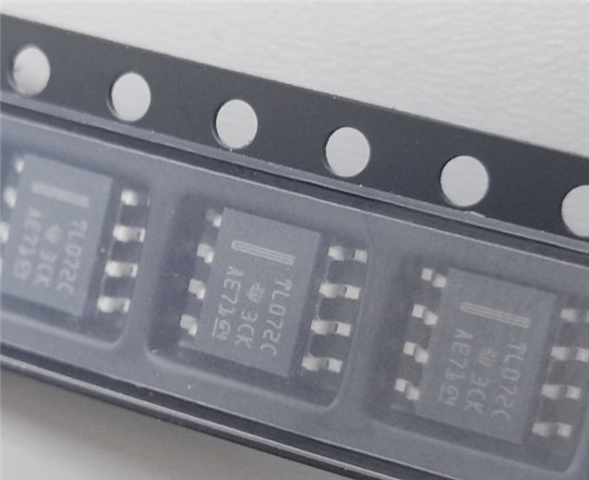

We have procured the TL072CDR part from Malaysia under PCN no: 20220615003.1. However, we encountered a functional performance issue, with 100% of the parts failing during functional testing.

Could you please provide the datasheet details for the parts before and after the implementation of this PCN?

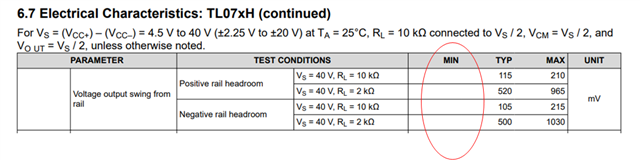

We need to understand if there are any electrical specification differences due to fabrication process changes. Could you please investigate this for us?

To address this issue, we used older parts from Mexico, which were previously procured and placed on boards, and all of them passed functional testing.

This issue has caused a production stoppage. We need your immediate attention.

Thanking you,

Rajani.M

HTS