Other Parts Discussed in Thread: OPA991, TLV888

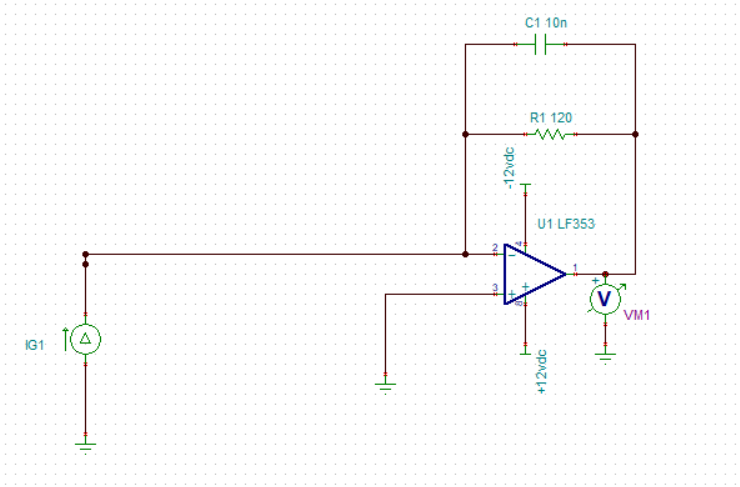

Hello, I am designing a transimpedance circuit, which will receive a current between the intervals of 0 - 30mA. This current comes from one of the electrodes that I am using to measure conductivity, the system has been parameterized to measure conductivities from 0 to 9 mS. Making all the adjustments I have generated an excitation signal towards the electrodes of +/- 10 V square wave at a frequency of 5 kHz .... I have already made certain measurements and I have obtained the current range of 0 - 30mA (Bipolar square wave of 5 kHz, 50% duty cycle) Now the next step is that I want to convert this current signal into a voltage signal of +/- 3.5V bipolar square. I have calculated the Transimpedance resistance which has given me 116 Ohm and I have put a 10nF capacitor in parallel. As an amplifier I have used the LF353, but I am not getting good results. I've actually implemented the attached circuit, but I notice that when the conductivity is 9 mS (measured with a commercial meter), the amplifier overheats, distorts the waveform, and clips on the negative side. I'd like to know if this amplifier is suitable for this application, and if not, which one you recommend. I've attached some images of the schematic and the waveform generated at the output of the transimpedance amplifier.

This is the graph when the current passing through the electrodes is approximately +/- 30 mA. The graph represents the output of the transimpedance amplifier. The negative side should be -3.5 V, but it isn't. I'm powering the op amp with +/- 12 V.

I hope you can help me select the op amp if it's incorrectly selected.

Alvaro Tasco