Other Parts Discussed in Thread: SENSOREMULATOREVM, , PGA309

I recently purchased PGA309EVM-USB and SensorEmulatorEVM. I try to use PGA309EVM to generate a coefficient to correct for nonlinearity.

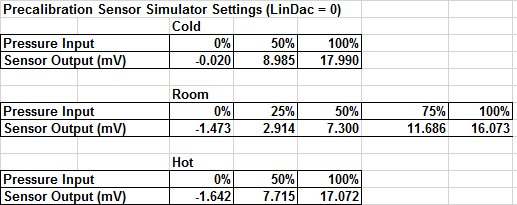

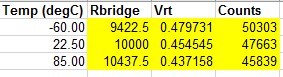

I change necessary jumper to use external sensor. I also input specification of sensor to Generate_Sim_Values.xls and set up sensor emulator according to the following output.

Here is my connection from sensor emulator to PGA309 testboard,

-+12/-12/GND to external power supply

-Vexc >>>>>>> Vsensor

-Vin+ >>>>>>> Vin2

-Vin- >>>>>>> Vin1

-Buff Temp >>>>>>> Vtemp

-GND >>>>>>> GND

I did find Calibration = USB_DAQ + PGA309EVM.ppt on the E2E site about how to setup for calibration. I follow the instruction and

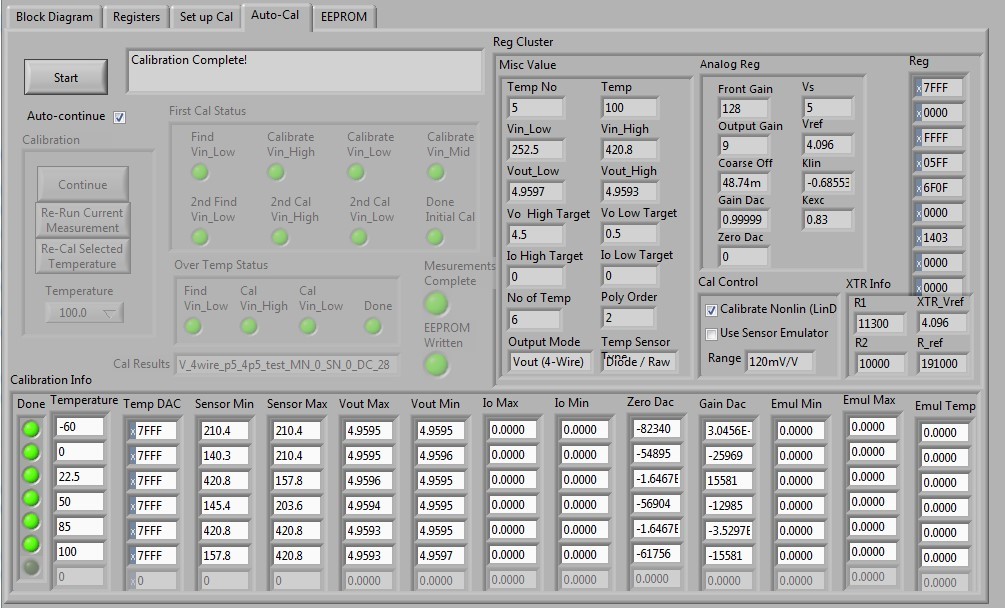

assume is the same for using external sensor emulator. I also uncheck use sensor emulator on create model page. I got the

following calibration info and EEPROM result.

[General Info]

Date=7/16/2019

Time="9:23 AM"

[Paths]

Model path="/C/Program Files (x86)/proj_PGA309EVM-USB/Model_Files/V_4wire_p5_4p5_test.txt"

Pre-Cal path="/C/Program Files (x86)/proj_PGA309EVM-USB/Pre_Cal_Files/V_4wire_p5_4p5_test.txt"

Sensor Emulator path="<Not A Path>"

[EEPROM Data]

Addr0=21577

Addr2=0

Addr4=0

Addr6=1535

Addr8=28431

Addr10=0

Addr12=5123

Addr14=8869

Addr16=32767

Addr18=0

Addr20=0

Addr22=32767

Addr24=0

Addr26=0

Addr28=32767

Addr30=0

Addr32=0

Addr34=32767

Addr36=0

Addr38=0

Addr40=32767

Addr42=0

Addr44=0

Addr46=32767

Addr48=0

Addr50=0

Addr52=32767

Addr54=0

Addr56=0

Addr58=32767

Addr60=0

Addr62=0

Addr64=32767

Addr66=0

Addr68=0

Addr70=32767

Addr72=0

Addr74=0

Addr76=32767

Addr78=0

Addr80=0

Addr82=32767

Addr84=0

Addr86=0

Addr88=32767

Addr90=0

Addr92=0

Addr94=32767

Addr96=0

Addr98=0

Addr100=32767

Addr102=0

Addr104=0

Addr106=32767

Addr108=0

Addr110=0

Addr112=32767

Addr114=0

Addr116=0

Addr118=32767

Addr120=0

Addr122=17

Here are my questions and please correct me if anything I am doing is wrong

1.from old user guide sboa103c.pdf page 40. it talks about generate a coefficient that the PGA309 will use to correct for

nolinearity verses applied pressure. Where can I find this old spread sheet and how can I generate coefficient with the

new PGA309 software.

2.When I connect external sensor emulator with PGA309 to run calibration, do I leave the rotary switch S1 and S2 with no

channel is selected or change S1 and S2 as the calibration runs.

3.After the calibration is finish, it generate a txt file in EEPROM result. but I don’t understand the result. Where can I

find more info about EEPROM data.

Thank you,