Other Parts Discussed in Thread: ADS124S08, OPA317, LMC6082, INA326, INA333

Hi,

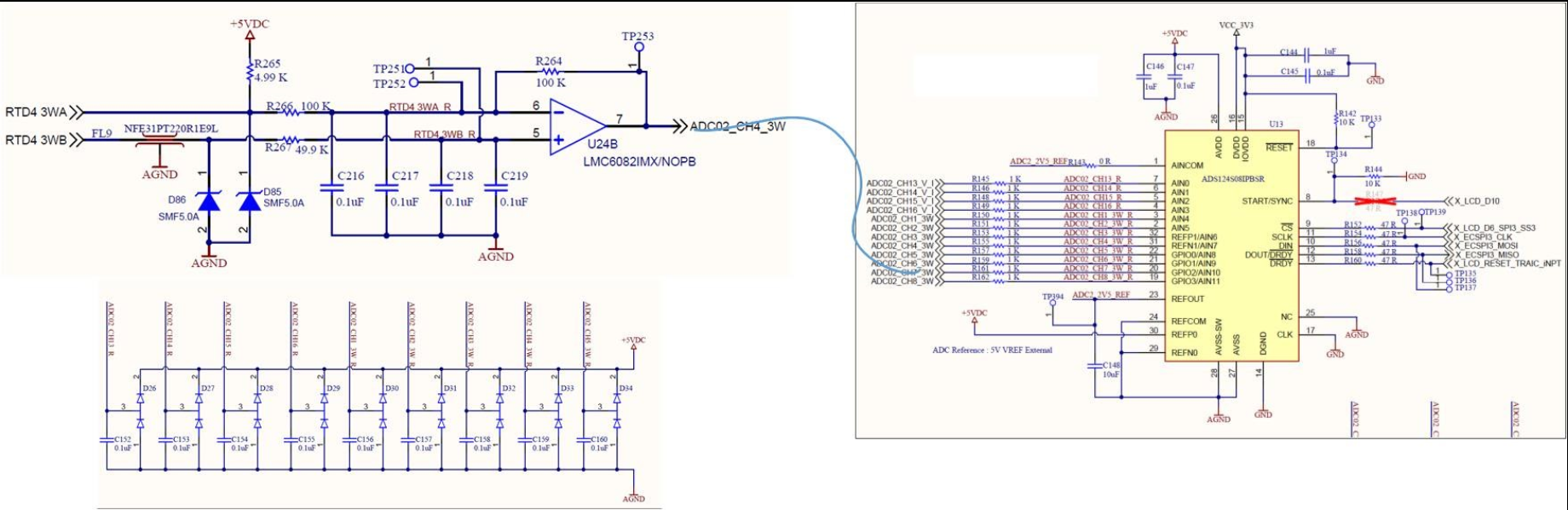

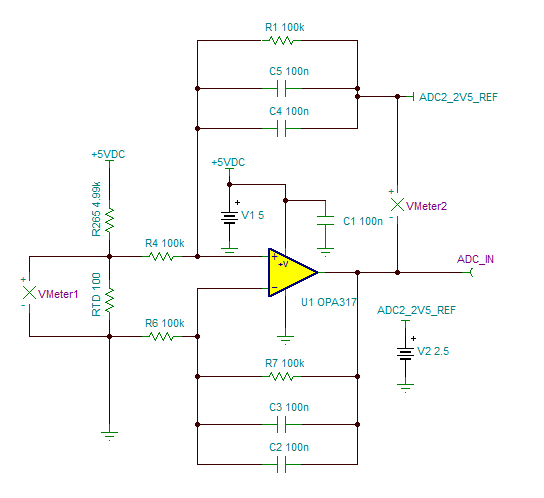

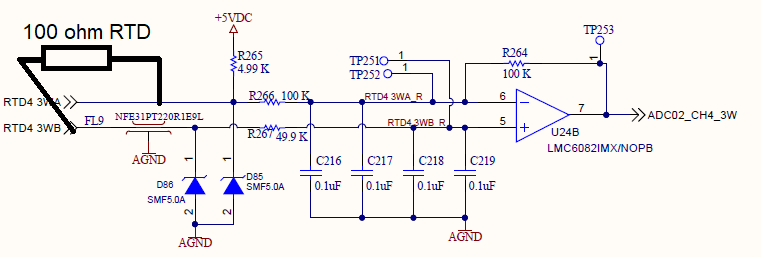

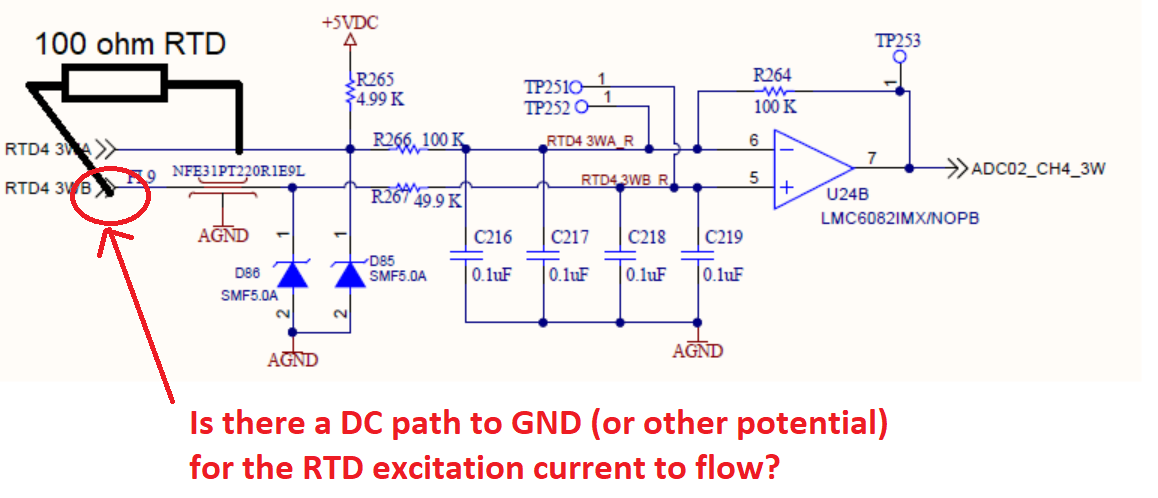

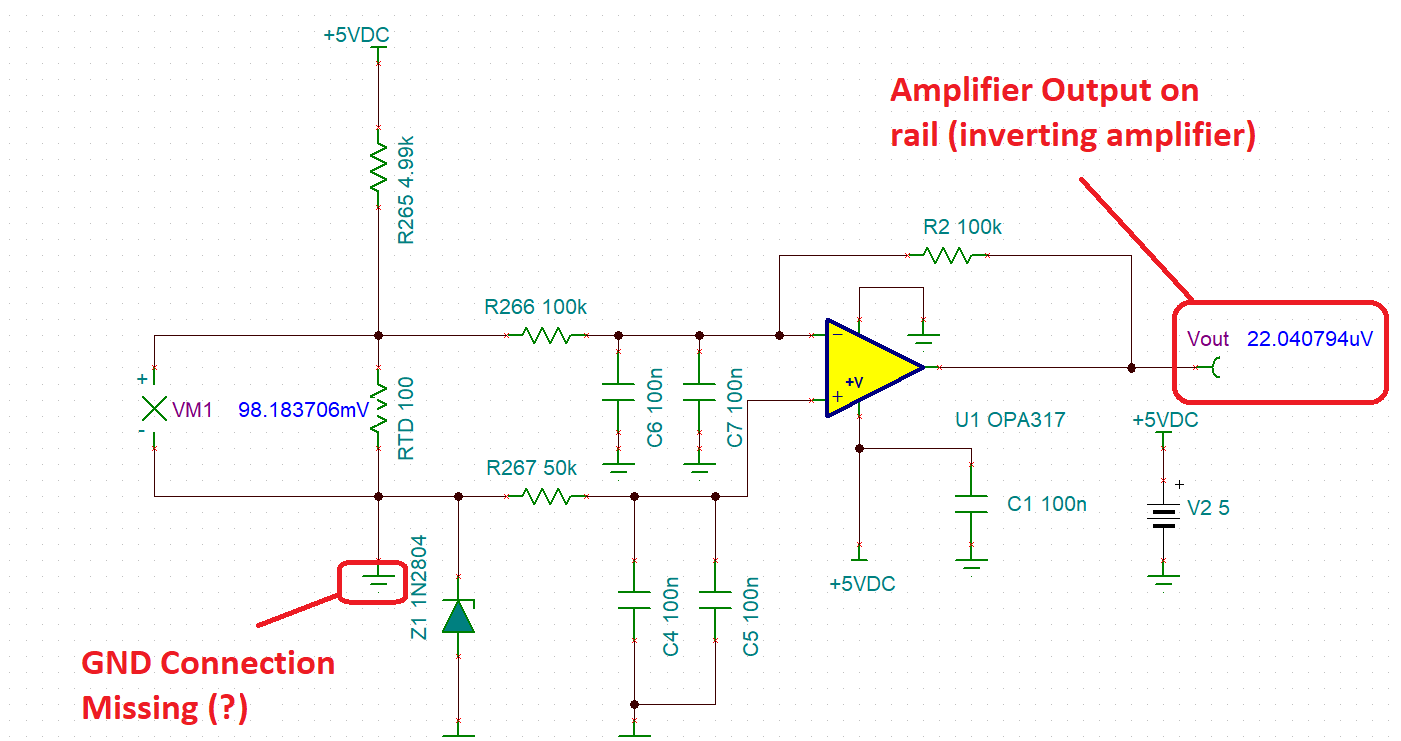

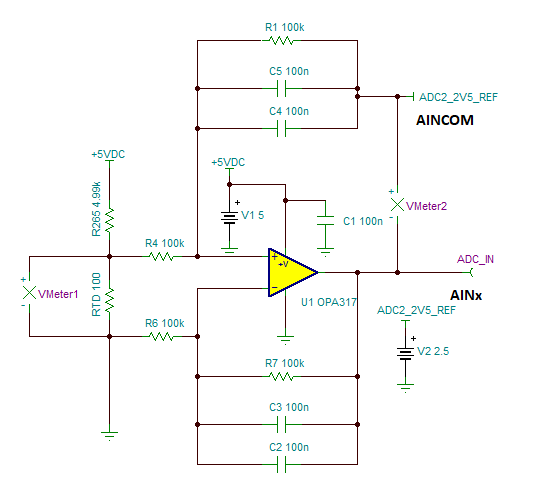

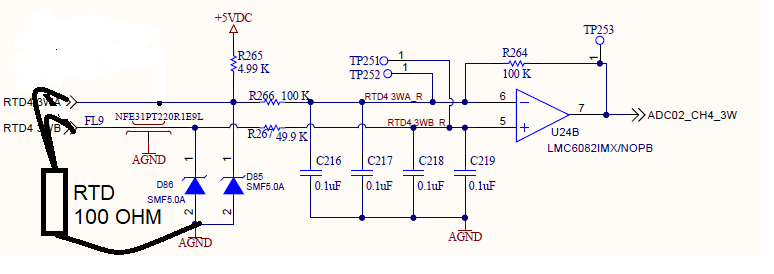

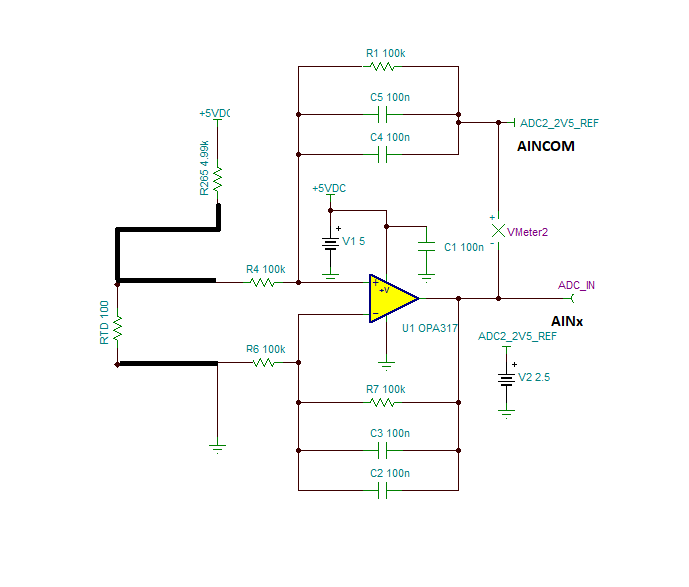

When we LMC6082IMX opamp for 24 bit ADC application. found that the LMC6082IMX offset voltage is more. So found low offset voltage opamp OPA2317 to replace the LMC6082IMX.

considering offset voltage the OPA2317 is excellent; apart from offset voltage any other critical parameter need to check ??

OP2317 will work for my circuit ??