Other Parts Discussed in Thread: DS90LV027, DS90LV017A, SN65LVDT41, DS90LV028A, SN74LVC125A, SN74HCS125, DS90LV012A, TXU0304-Q1, TXU0304, DSLVDS1047, DSLVDS1048, TCA9803, TXB0104, TPD2E009, AM26C32, AM26C31, AM26LV32, AM26LV31, THVD1500, THVD1400, P82B96, DS8921

Dear Community,

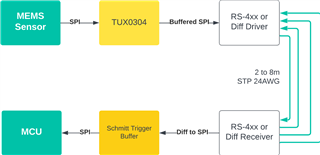

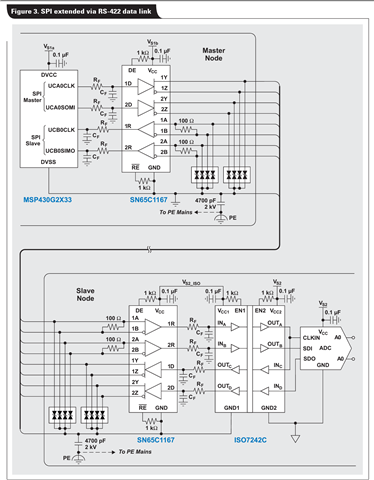

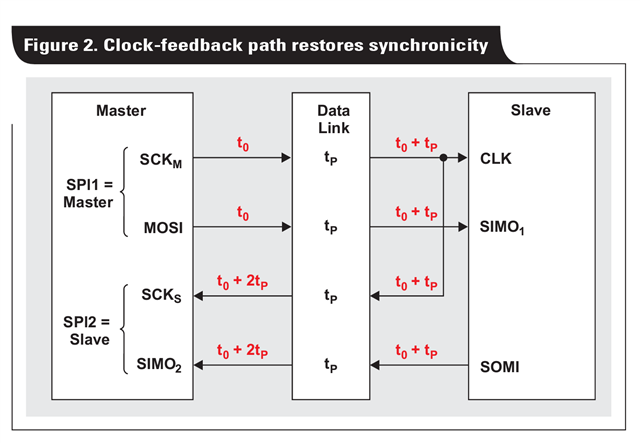

We are currently working on a cost-optimized Condition Monitoring System and are facing a challenge in interfacing our MEMS sensor (IIS3DWB) with the MCU STM32G474 over a distance of 2-4 meters. While we have found multiple buffers and level-translators available for I2C communication, we are unable to locate a suitable solution for our SPI sensor communication over this 2-4 meter distance. We require a robust approach to ensure reliable data transfer from the sensor to the MCU, with a target data rate of up to 150KB/s (or 2MHz clock speeds)

We kindly request your suggestions and expertise in helping us find a suitable solution for this use case. Any guidance or recommended approaches for extending SPI communication over long distances, specifically in relation to our MEMS sensor and the MCU, would be greatly appreciated.

Thank you in advance for your support and insights