Hi, I'm using a pair of TM4C123G evaluation boards trying to get an SSI channel to work. These boards have TM4C123GH6PM microcontrollers. I'm using a recent version of Code Composer Studio and TivaWare 2.2.0.295.

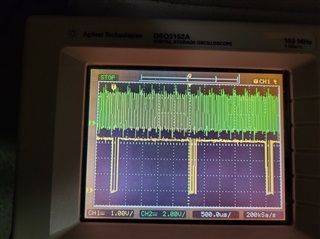

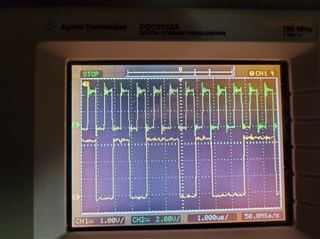

Between the boards we have SSI1 clock connected, and SSI1 RX/TX crosswired - RX on board 1 connects to TX on board 2 and vice versa. I have two CCS projects, a SPI master and a SPI slave. I'm simply trying to transmit "1234" from master to slave twice a second. We've looked at the lines on a scope, we see a 1 MHz clock and 2 Hz data. From that it seems the master side is working as expected. This issue I have is on the slave. After setup I'm in a loop trying to read data, and the first call to SSIDataGet never returns. Code for both sides below. What am I doing wrong ?!

// SPI master

#include <stdint.h>

#include "inc/hw_memmap.h"

#include "driverlib/gpio.h"

#include "driverlib/pin_map.h"

#include "driverlib/ssi.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

/////////////////////////////////////////////////////////////////////////////

void InitializeSystem()

{

// Set the clocking to run directly from the crystal.

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN | SYSCTL_XTAL_16MHZ);

// Initialize UART1 to 115200 baud, N-8-1

// UART1 : GPIO Port B : UART1RX = PB0 : UART1TX = PB1

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART1);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

GPIOPinConfigure(GPIO_PB0_U1RX);

GPIOPinConfigure(GPIO_PB1_U1TX);

GPIOPinTypeUART(GPIO_PORTB_BASE, GPIO_PIN_0 | GPIO_PIN_1);

UARTConfigSetExpClk(UART1_BASE, SysCtlClockGet(), 115200,

UART_CONFIG_WLEN_8 | UART_CONFIG_STOP_ONE | UART_CONFIG_PAR_NONE);

}

/////////////////////////////////////////////////////////////////////////////

void InitializeSSI1()

{

// Enable the SSI1 peripheral for use.

SysCtlPeripheralEnable(SYSCTL_PERIPH_SSI1);

// We have PD0 (SSI1 Clk), PD2 (SSI1 Rx), and PD3 (SSI1 Tx) connected.

// (Odd thing, pins/ports for SSI1 are the same as SSI3 ?!)

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOD);

// Configure the pin muxing for SSI functions

GPIOPinConfigure(GPIO_PD0_SSI1CLK);

GPIOPinConfigure(GPIO_PD1_SSI1FSS);

GPIOPinConfigure(GPIO_PD2_SSI1RX);

GPIOPinConfigure(GPIO_PD3_SSI1TX);

// Configure the GPIO settings for the SSI pins. This function also gives

// control of these pins to the SSI hardware.

GPIOPinTypeSSI(GPIO_PORTD_BASE, GPIO_PIN_0 | GPIO_PIN_1 | GPIO_PIN_2 | GPIO_PIN_3);

// Configure and enable the SSI port for SPI master mode.

SSIDisable(SSI1_BASE);

SSIConfigSetExpClk(SSI1_BASE, SysCtlClockGet(), SSI_FRF_MOTO_MODE_0, SSI_MODE_MASTER, 1000000, 8);

// Advance mode settings. Legacy is default. I've seen several mentions

// in technical forum discussions that when writing as SSI master, you

// need "dummy" reads (in legacy mode)?

//SSIAdvModeSet(SSI1_BASE, SSI_ADV_MODE_WRITE);

// Enable the SSI module.

SSIEnable(SSI1_BASE);

// Read residual data from the SSI port so we don't read any junk.

uint32_t RxData;

while (SSIDataGetNonBlocking(SSI1_BASE, &RxData))

{

}

}

/////////////////////////////////////////////////////////////////////////////

int main(void)

{

InitializeSystem();

InitializeSSI1();

// A call to SysCtlDelay with a delay count of 1 takes 3 clock cycles

unsigned int nDelayOneMillisecond = (SysCtlClockGet() / 3) / 1000;

const unsigned int nDelayCount = 500 /* milliseconds */ * nDelayOneMillisecond;

const unsigned int Message[4] = { '1', '2', '3', '4' };

uint32_t RxData = 0;

while (true)

{

// Transmit on SPI and UART every <n> milliseconds.

SysCtlDelay(nDelayCount);

for (unsigned int nByte = 0 ; nByte < 4 ; nByte++)

{

while (SSIDataGetNonBlocking(SSI1_BASE, &RxData)) {}

SSIDataPut(SSI1_BASE, Message[nByte]);

// SSIDataGetNonBlocking(SSI1_BASE, &RxData);

UARTCharPut(UART1_BASE, (unsigned char)Message[nByte]);

}

}

}

// SPI slave

#include <stdint.h>

#include "inc/hw_memmap.h"

#include "driverlib/gpio.h"

#include "driverlib/pin_map.h"

#include "driverlib/ssi.h"

#include "driverlib/sysctl.h"

#include "driverlib/uart.h"

/////////////////////////////////////////////////////////////////////////////

void InitializeSystem()

{

// Set the clocking to run directly from the crystal.

SysCtlClockSet(SYSCTL_SYSDIV_1 | SYSCTL_USE_OSC | SYSCTL_OSC_MAIN | SYSCTL_XTAL_16MHZ);

// Initialize UART1 to 115200 baud, N-8-1

// UART1 : GPIO Port B : UART1RX = PB0 : UART1TX = PB1

SysCtlPeripheralEnable(SYSCTL_PERIPH_UART1);

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOB);

GPIOPinConfigure(GPIO_PB0_U1RX);

GPIOPinConfigure(GPIO_PB1_U1TX);

GPIOPinTypeUART(GPIO_PORTB_BASE, GPIO_PIN_0 | GPIO_PIN_1);

UARTConfigSetExpClk(UART1_BASE, SysCtlClockGet(), 115200,

UART_CONFIG_WLEN_8 | UART_CONFIG_STOP_ONE | UART_CONFIG_PAR_NONE);

}

/////////////////////////////////////////////////////////////////////////////

void InitializeSSI1()

{

// Enable the SSI1 peripheral for use.

SysCtlPeripheralEnable(SYSCTL_PERIPH_SSI1);

// We have PD0 (SSI1 Clk), PD2 (SSI1 Rx), and PD3 (SSI1 Tx) connected.

// (Odd thing, pins/ports for SSI1 are the same as SSI3 ?!)

SysCtlPeripheralEnable(SYSCTL_PERIPH_GPIOD);

// Configure the pin muxing for SSI functions

GPIOPinConfigure(GPIO_PD0_SSI1CLK);

GPIOPinConfigure(GPIO_PD1_SSI1FSS);

GPIOPinConfigure(GPIO_PD2_SSI1RX);

GPIOPinConfigure(GPIO_PD3_SSI1TX);

// Configure the GPIO settings for the SSI pins. This function also gives

// control of these pins to the SSI hardware.

GPIOPinTypeSSI(GPIO_PORTD_BASE, GPIO_PIN_0 | GPIO_PIN_1 | GPIO_PIN_2 | GPIO_PIN_3);

// Configure and enable the SSI port for SPI slave mode.

SSIDisable(SSI1_BASE);

SSIConfigSetExpClk(SSI1_BASE, SysCtlClockGet(), SSI_FRF_MOTO_MODE_0, SSI_MODE_SLAVE, 1000000, 8);

//SSIConfigSetExpClk(SSI1_BASE, SysCtlClockGet(), SSI_FRF_MOTO_MODE_0, SSI_MODE_SLAVE_OD, 1000000, 8);

// Advance mode settings. Legacy is default.

//SSIAdvModeSet(SSI1_BASE, SSI_ADV_MODE_LEGACY);

// Enable the SSI module.

SSIEnable(SSI1_BASE);

// Read residual data from the SSI port so we don't read any junk.

uint32_t RxData;

while (SSIDataGetNonBlocking(SSI1_BASE, &RxData))

{

}

}

/////////////////////////////////////////////////////////////////////////////

int main(void)

{

// Initialize the system

InitializeSystem();

InitializeSSI1();

unsigned int nByte = 0;

while (true)

{

// Get next charater on SPI and forward to UART

SSIDataPut(SSI1_BASE, 0); // dummy write?

SSIDataGet(SSI1_BASE, &nByte);

UARTCharPut(UART1_BASE, (unsigned char)nByte);

}

}