Other Parts Discussed in Thread: TMS320F280049C, , C2000WARE

Hi,team

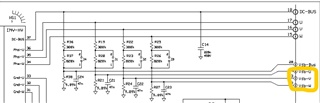

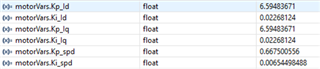

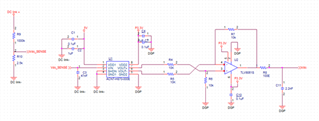

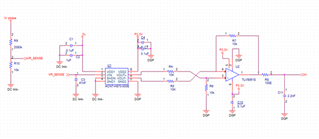

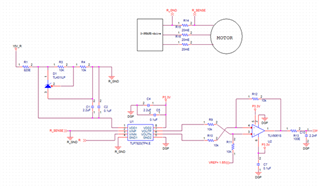

We are using TMS320F280049C controller, and Sensor less FOC code files given by TI,("C:\ti\c2000\C2000Ware_MotorControl_SDK_3_00_01_00\solutions\tmdshvmtrinspin\f28004x\ccs\sensorless_foc")

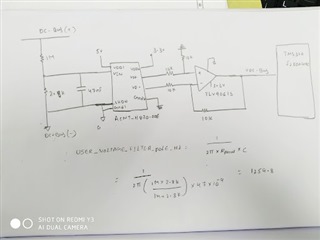

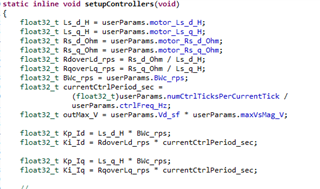

We designed own HV-kit with 3phase input supply, which generate 800Vdc bus, and we are using motor witch is having voltage 260V and current 7.4A ,is that FOC library support to my application ?

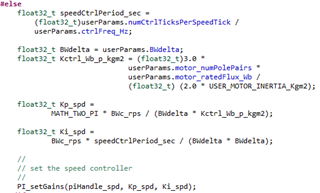

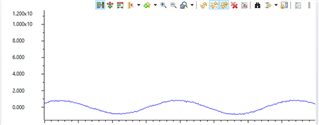

1.we need to control the speed of my motor, how can i control ?

2.What are the parameters i need to change to control the speed (note : we familiar with motorVars.speedRefHz ) how can i control the output voltage of the inverter?