Hi All

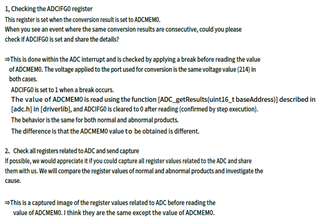

My custamer use ADC switching between A1 and A3.

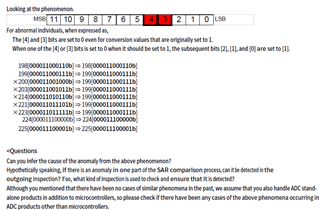

The "ADCMEM0" values of A1 and A3 get the same value for a certain interval every 64 cycles.

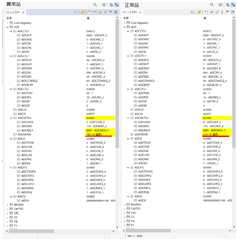

Standard Product: 194,195,196,197,198,199,200,201,202,...,223,224,225,226,...,261,262,263,264,265,266

Error Product: 194,195,196,197,198,199,199,199,...,199,224,225,226,...,261,262,263,263,263

Is there any cause for this phenomenon?

This phenomenon is occurring in only one unit during the inspection of a product in mass production.

Best Regards,

Ito