Tool/software:

Dear Cash Hao11,

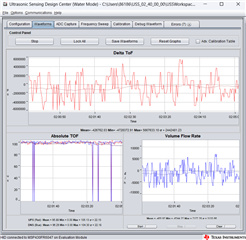

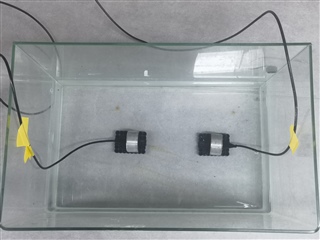

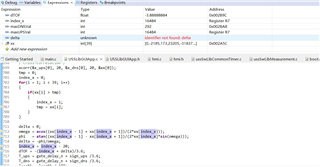

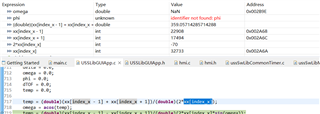

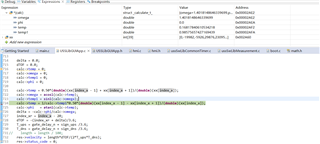

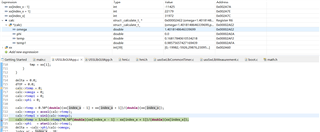

I have been researching whether the MSP430FR6047 chip can be used for open channel flow measurement in the range of 1-5 meters, as opposed to the pipe measurement provided in the official documentation. During a recent experiment, I observed some phenomena that I will describe below. In this experiment, the sound path distance was 0.8 meters, and the location was an indoor water tank.

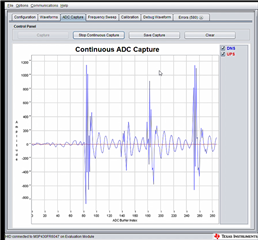

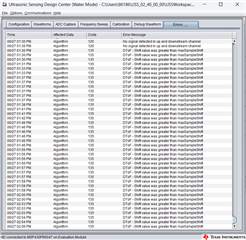

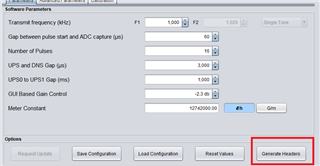

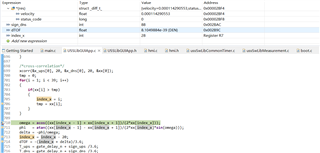

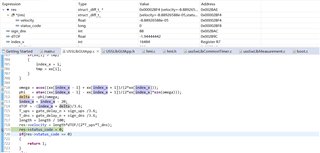

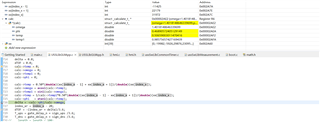

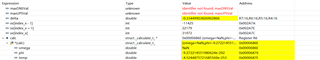

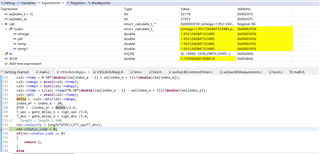

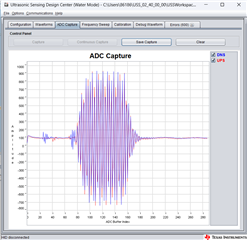

First, I completed the connection of the ultrasonic transducer and the development board (MSP430FR6047) following the steps in the official manual, and then I flashed the corresponding bin file. After setting the parameters on the USS GUI, I opened the ADC capture interface and saw a very strange waveform. The UPS waveform was almost a straight line (compared to the standard capture waveform provided in the official documentation).

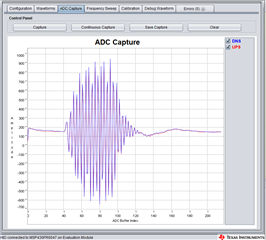

What's even stranger is that when I checked the wiring and reconnected, the waveform amplitude dropped directly to 20-30 (with all other USS parameters remaining unchanged).

I cannot understand the underlying reason for this and would appreciate your help in solving this mystery.