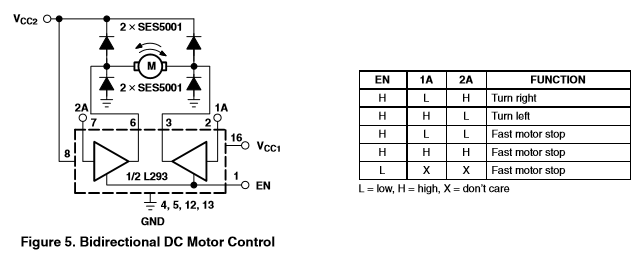

hello,my task is DC motor control in CODECOMPOSER by using msp430 ,model of G2553 and the target is making the motor in two direction,forward and backword also by using Pwm to turn that motor slow and fast by using buttons.Can you help me to write that in code composer.The MOTOR driver is L293D.

THANKS A LOT.I have a written code here but i am not sure about it,can somebody check it or help me with that code.