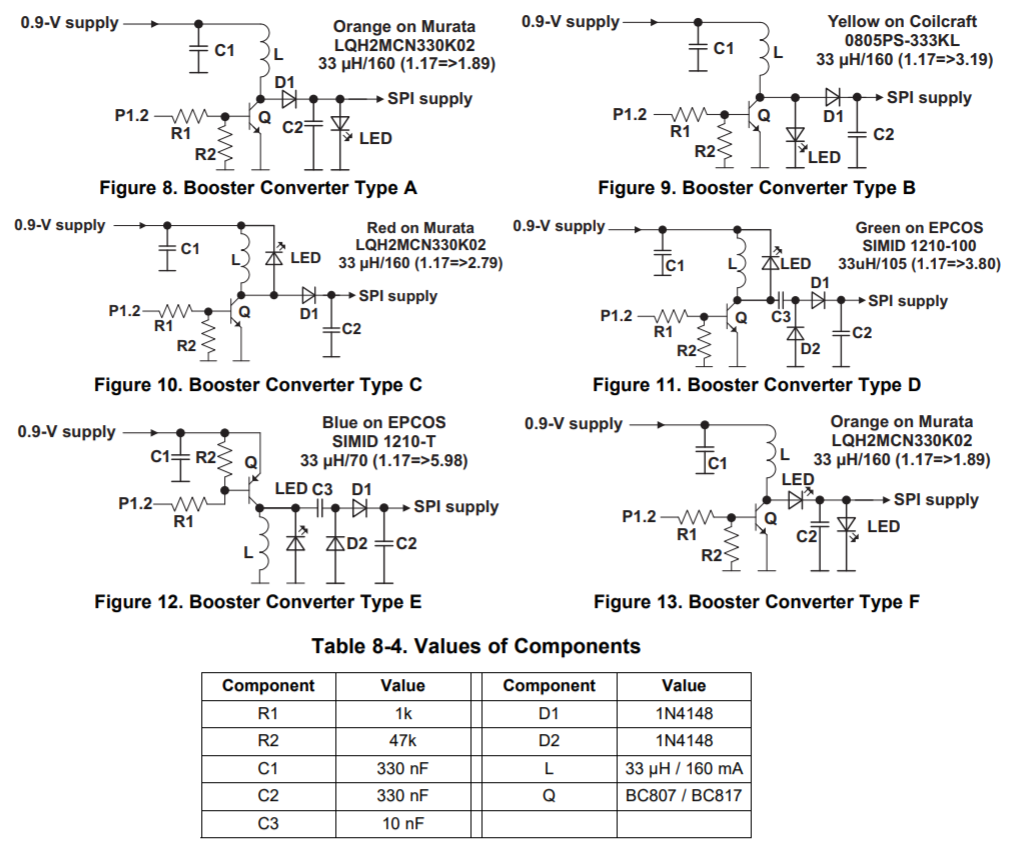

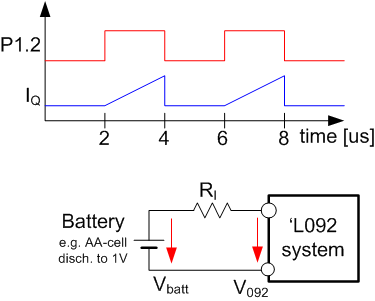

Refferring to SLAA472, MSP430L092 Development Guide (Figure 8), and SLAU321 (Figure 13) etc, a L092 hardware board is developed. Except for the abnormal replacement of LED with 1N4148, the basic work is stable. But the following problems are not clear:

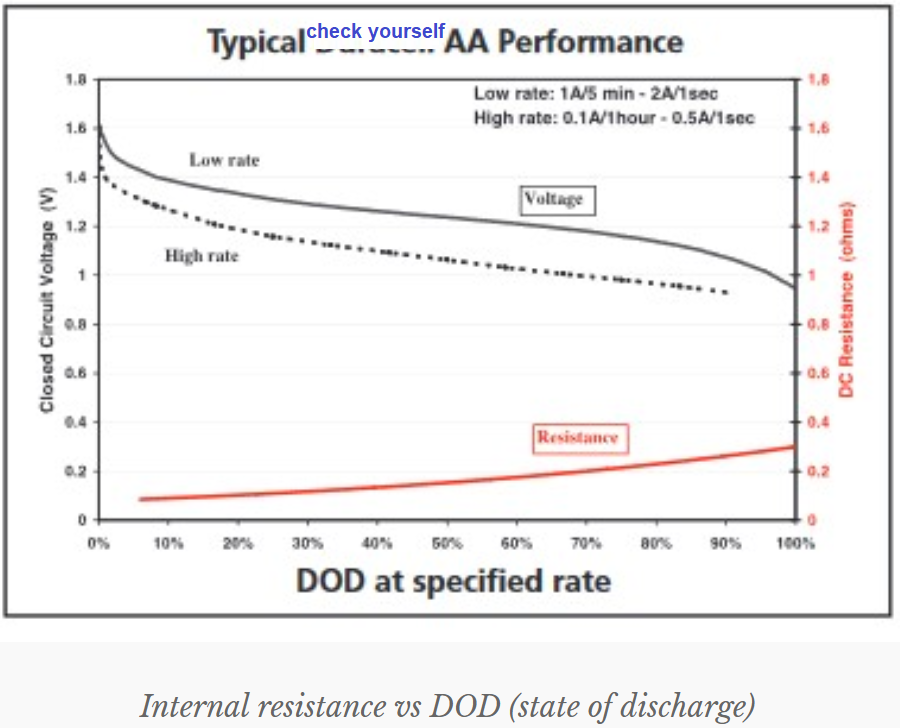

1, The working voltage can not reach 0.9V. Near 1v, the LED began to display download intermittently.

2, When working voltage is 1.3v, it works normally. But the current measured by the ammeter raeches 0.15mA and at that time the LED flashes continuously and quickly, I wonder why . When we work, the power supply to be contained by load, so we also will meet this flashing and can not work normally.

keeping forward to hearing from your answer.