Other Parts Discussed in Thread: MCF8316A, MCT8316Z

Hello,

I asked and solved the problem that the motor does not rotate well in the closed loop.

But I still have some problems.

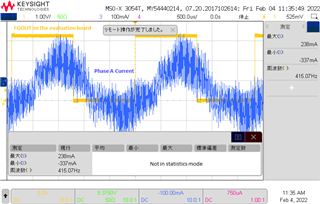

(1) Motor does not rotate stably at low speed (30 [fps])

When the speed drops below about 40 [fps], it often stops.

(2) If the torque load fluctuates, the motor cannot maintain its speed.

Especially low speed rotation is difficult with my low power motor.

My motor has an encoder, but it doesn't have A, B, C phase Hall sensors...

{

"signature": "oneui-register-data",

"data": [

[

{

"idx": 0,

"id": "isd_config",

"value": "0x04638C20"

},

{

"idx": 1,

"id": "rev_drive_config",

"value": "0x283AF064"

},

{

"idx": 2,

"id": "motor_startup1",

"value": "0x0A8407D0"

},

{

"idx": 3,

"id": "motor_startup2",

"value": "0x1382E034"

},

{

"idx": 4,

"id": "closed_loop1",

"value": "0x0D3201B4"

},

{

"idx": 5,

"id": "closed_loop2",

"value": "0x1AADD858"

},

{

"idx": 6,

"id": "closed_loop3",

"value": "0x28800000"

},

{

"idx": 7,

"id": "closed_loop4",

"value": "0x0A004870"

},

{

"idx": 8,

"id": "speed_profiles1",

"value": "0x000007E8"

},

{

"idx": 9,

"id": "speed_profiles2",

"value": "0x70000000"

},

{

"idx": 10,

"id": "speed_profiles3",

"value": "0x00000000"

},

{

"idx": 11,

"id": "speed_profiles4",

"value": "0x00000000"

},

{

"idx": 12,

"id": "speed_profiles5",

"value": "0x00000000"

},

{

"idx": 13,

"id": "speed_profiles6",

"value": "0x00000000"

}

],

[

{

"idx": 0,

"id": "fault_config1",

"value": "0x5FE8820E"

},

{

"idx": 1,

"id": "fault_config2",

"value": "0x74008000"

}

],

[

{

"idx": 0,

"id": "pin_config",

"value": "0x2DD0E480"

},

{

"idx": 1,

"id": "device_config1",

"value": "0x08000001"

},

{

"idx": 2,

"id": "device_config2",

"value": "0x00003000"

},

{

"idx": 3,

"id": "peri_config1",

"value": "0x00000000"

},

{

"idx": 4,

"id": "gd_config1",

"value": "0x00000000"

},

{

"idx": 5,

"id": "gd_config2",

"value": "0x00000000"

}

],

[

{

"idx": 0,

"id": "ana_trim3",

"value": "0x48004800"

},

{

"idx": 1,

"id": "ana_trim4",

"value": "0x00000000"

},

{

"idx": 2,

"id": "ana_trim5",

"value": "0x00000013"

},

{

"idx": 3,

"id": "ana_trim6",

"value": "0x00000000"

},

{

"idx": 4,

"id": "ana_trim7",

"value": "0x00000000"

},

{

"idx": 5,

"id": "ana_trim8",

"value": "0x00005C95"

},

{

"idx": 6,

"id": "ana_trim9",

"value": "0x008D55D7"

},

{

"idx": 7,

"id": "ana_trim10",

"value": "0x537E013A"

}

],

[

{

"idx": 0,

"id": "int_algo_1",

"value": "0x00020000"

},

{

"idx": 1,

"id": "int_algo_2",

"value": "0x00000140"

}

],

[

{

"idx": 0,

"id": "gate_driver_fault_status",

"value": "0x00000000"

},

{

"idx": 1,

"id": "controller_fault_status",

"value": "0x00000000"

}

],

[

{

"idx": 0,

"id": "algo_status",

"value": "0x0E7E0000"

},

{

"idx": 1,

"id": "mtr_params",

"value": "0x00000000"

},

{

"idx": 2,

"id": "algo_status_mpet",

"value": "0x0A000000"

}

],

[

{

"idx": 0,

"id": "algo_ctrl1",

"value": "0x00000000"

}

],

[

{

"idx": 0,

"id": "algo_debug1",

"value": "0x00000000"

},

{

"idx": 1,

"id": "algo_debug2",

"value": "0x00000000"

},

{

"idx": 2,

"id": "current_pi",

"value": "0x0005813D"

},

{

"idx": 3,

"id": "speed_pi",

"value": "0x00000000"

}

],

[

{

"idx": 0,

"id": "speed_ref_closed_loop",

"value": "0x00000000"

},

{

"idx": 1,

"id": "vm_voltage",

"value": "0x0348C000"

},

{

"idx": 2,

"id": "voltage_gain_feedback",

"value": "0x00000001"

},

{

"idx": 3,

"id": "csa_gain_feedback",

"value": "0x00000003"

},

{

"idx": 4,

"id": "phase_voltage_va",

"value": "0x00000000"

},

{

"idx": 5,

"id": "phase_voltage_vb",

"value": "0x00000000"

},

{

"idx": 6,

"id": "phase_voltage_vc",

"value": "0x00000000"

},

{

"idx": 7,

"id": "id_ref_closed_loop",

"value": "0x00000000"

},

{

"idx": 8,

"id": "iq_ref_closed_loop",

"value": "0x00000000"

},

{

"idx": 9,

"id": "id",

"value": "0x00000000"

},

{

"idx": 10,

"id": "iq",

"value": "0x00000000"

},

{

"idx": 11,

"id": "vd",

"value": "0x00000000"

},

{

"idx": 12,

"id": "vq",

"value": "0x00000000"

},

{

"idx": 13,

"id": "ialpha",

"value": "0x00000000"

},

{

"idx": 14,

"id": "ibeta",

"value": "0x00000000"

},

{

"idx": 15,

"id": "valpha",

"value": "0x00000000"

},

{

"idx": 16,

"id": "vbeta",

"value": "0x00000000"

},

{

"idx": 17,

"id": "bus_current",

"value": "0xFFFFFF9C"

},

{

"idx": 18,

"id": "ipd_state",

"value": "0x00000000"

},

{

"idx": 19,

"id": "isd_state",

"value": "0x00000000"

},

{

"idx": 20,

"id": "algorithm_state",

"value": "0x00000000"

},

{

"idx": 21,

"id": "phase_current_a",

"value": "0x00000000"

},

{

"idx": 22,

"id": "phase_current_b",

"value": "0x00000000"

},

{

"idx": 23,

"id": "phase_current_c",

"value": "0x00000000"

},

{

"idx": 24,

"id": "ipd_angle",

"value": "0x00000000"

},

{

"idx": 25,

"id": "isd_speed",

"value": "0x00000000"

},

{

"idx": 26,

"id": "speed_ref_open_loop",

"value": "0x00000000"

},

{

"idx": 27,

"id": "iq_ref_open_loop",

"value": "0x00000000"

},

{

"idx": 28,

"id": "iq_ref_rotor_align",

"value": "0x00000000"

},

{

"idx": 29,

"id": "ed",

"value": "0x00000000"

},

{

"idx": 30,

"id": "eq",

"value": "0x00000000"

},

{

"idx": 31,

"id": "theta_est",

"value": "0x00000000"

},

{

"idx": 32,

"id": "speed_fdbk",

"value": "0x00000000"

},

{

"idx": 33,

"id": "sin_commutation_angle",

"value": "0x0503BDA8"

},

{

"idx": 34,

"id": "cos_commutation_angle",

"value": "0x00000000"

}

]

]

}

Thanks,

Tetsuya K