Hi,

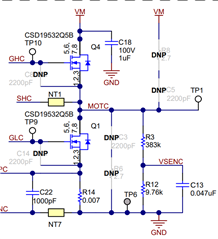

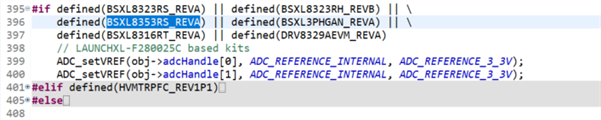

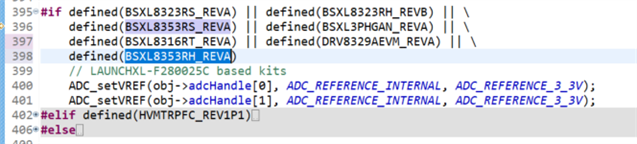

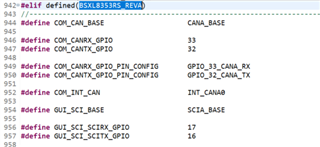

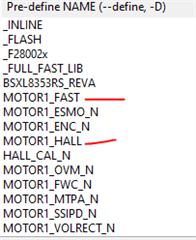

I am testing/developing firmware with DRV8353RS-EVM + LaunchXL- F280025C for my 2 wheeler BLDC Hub motor referring Universal Motor Control Lab. Testing with eval board in parallel, while my productiopn board is getting ready which can support higher current than DRV8353RS-EVM.

Please help in defining Motor related parameters in user_mtr1.h file.

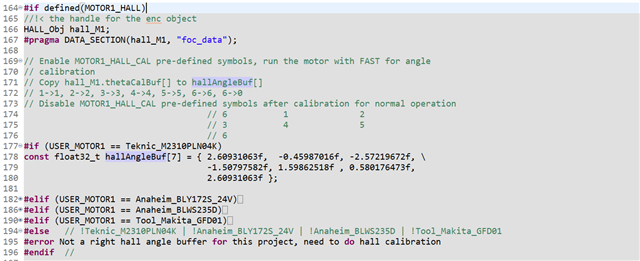

I am modifying the default Teknic_M2310PLN04K section in .h file.

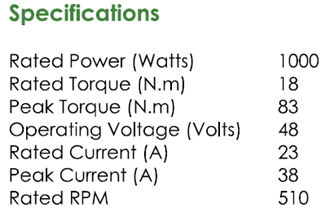

My Motor is a 2 wheeler BLDC hub motor . Unfortunately motor datasheet has only below information about motor electrical parameter.

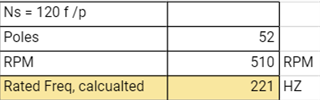

By shorting 2 phase wires and rotating shaft by hand, could find number of poles are 52.

Calcualted rated Freq as below

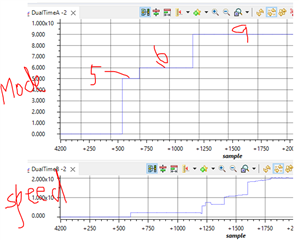

Please see the table below where I tried to fill the motor parameters needed in user_mtr1.h file. Please suggest the new parameters to be put for this motor .

| SN | #if (USER_MOTOR1 == Teknic_M2310PLN04K) | HUB MOTOR emfbl-10-48-1000-510 |

| 1 | #define USER_MOTOR1_TYPE MOTOR_TYPE_PM | |

| 2 | #define USER_MOTOR1_NUM_POLE_PAIRS (4) | 26 |

| 3 | #define USER_MOTOR1_Rr_Ohm (NULL) | |

| 4 | #define USER_MOTOR1_Rs_Ohm (0.393955578f) | |

| 5 | #define USER_MOTOR1_Ls_d_H (0.000190442806f) | |

| 6 | #define USER_MOTOR1_Ls_q_H (0.000190442806f) | |

| 7 | #define USER_MOTOR1_RATED_FLUX_VpHz (0.0399353318f) | |

| 8 | #define USER_MOTOR1_MAGNETIZING_CURRENT_A (NULL) | |

| 9 | #define USER_MOTOR1_RES_EST_CURRENT_A (1.5f) | |

| 10 | #define USER_MOTOR1_IND_EST_CURRENT_A (-1.0f) | |

| 11 | #define USER_MOTOR1_MAX_CURRENT_A (6.6f) | 23 (Shall I enter now 15 ? Eval board limitation) |

| 12 | #define USER_MOTOR1_FLUX_EXC_FREQ_Hz (60.0f) | |

| 13 | #define USER_MOTOR1_INERTIA_Kgm2 (7.06154e-06) | |

| 14 | #define USER_MOTOR1_RATED_VOLTAGE_V (24.0f) // V | 48 |

| 15 | #define USER_MOTOR1_FREQ_MIN_Hz (9.0f) // Hz | |

| 16 | #define USER_MOTOR1_FREQ_MAX_Hz (600.0f) // Hz | 221 |

| 16 | #define USER_MOTOR1_FREQ_LOW_Hz (5.0f) // Hz | |

| 19 | #define USER_MOTOR1_FREQ_HIGH_Hz (400.0f) // Hz | |

| 19 | #define USER_MOTOR1_VOLT_MIN_V (1.0f) // Volt | |

| 20 | #define USER_MOTOR1_VOLT_MAX_V (24.0f) // Volt | |

| 21 | #define USER_MOTOR1_FORCE_DELTA_A (0.05f) // A | |

| 22 | #define USER_MOTOR1_ALIGN_DELTA_A (0.01f) // A | |

| 23 | #define USER_MOTOR1_FLUX_CURRENT_A (0.5f) // A | |

| 24 | #define USER_MOTOR1_ALIGN_CURRENT_A (1.5f) // A | |

| 27 | #define USER_MOTOR1_STARTUP_CURRENT_A (3.5f) // A | |

| 28 | #define USER_MOTOR1_TORQUE_CURRENT_A (3.0f) // A | |

| 28 | #define USER_MOTOR1_OVER_CURRENT_A (7.5f) // A | |

| 29 | #define USER_MOTOR1_SPEED_START_Hz (35.0f) // Hz | |

| 30 | #define USER_MOTOR1_SPEED_FORCE_Hz (30.0f) // Hz | |

| 31 | #define USER_MOTOR1_ACCEL_START_Hzps (10.0f) // Hz/s | |

| 32 | #define USER_MOTOR1_ACCEL_MAX_Hzps (20.0f) // Hz/s | |

| 33 | #define USER_MOTOR1_SPEED_FS_Hz (3.0f) // Hz | |

| 34 | #define USER_MOTOR1_BRAKE_CURRENT_A (1.0f) // A | |

| 35 | #define USER_MOTOR1_BRAKE_TIME_DELAY (12000U) // 60s/5ms |

Thanks & Regards,

Anil