Other Parts Discussed in Thread: MCF8315A, , DRV8316, MCT8315A

Dear support team,

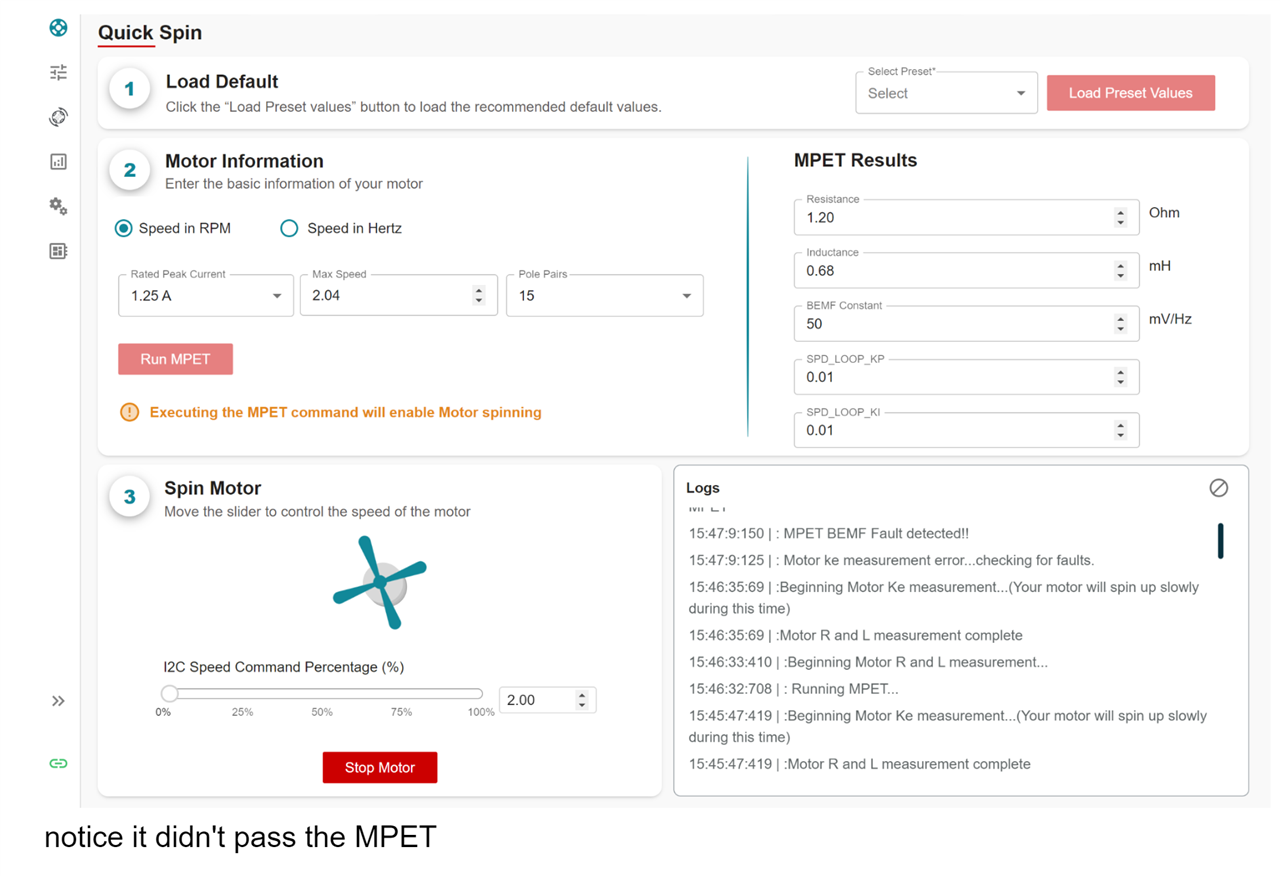

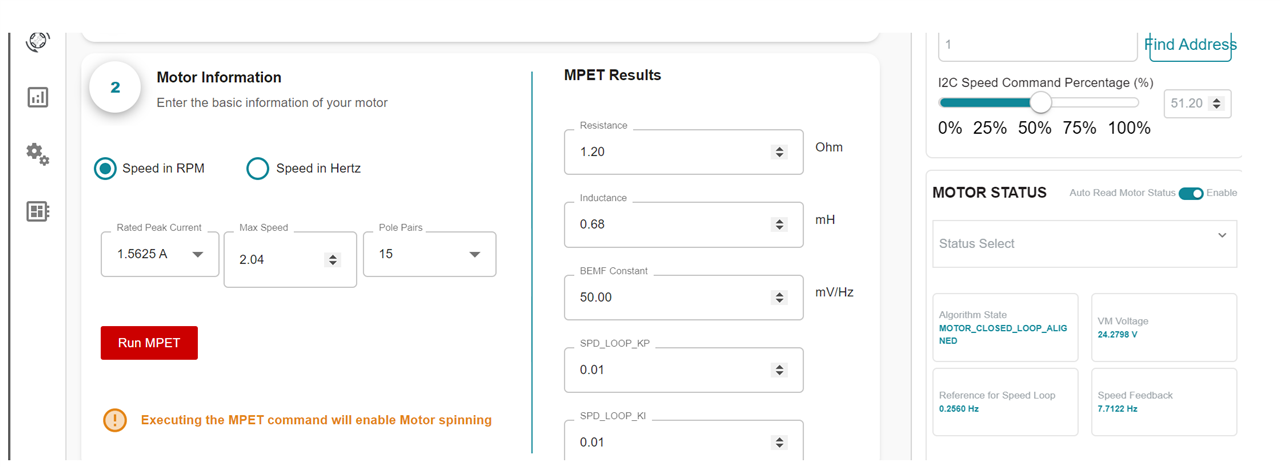

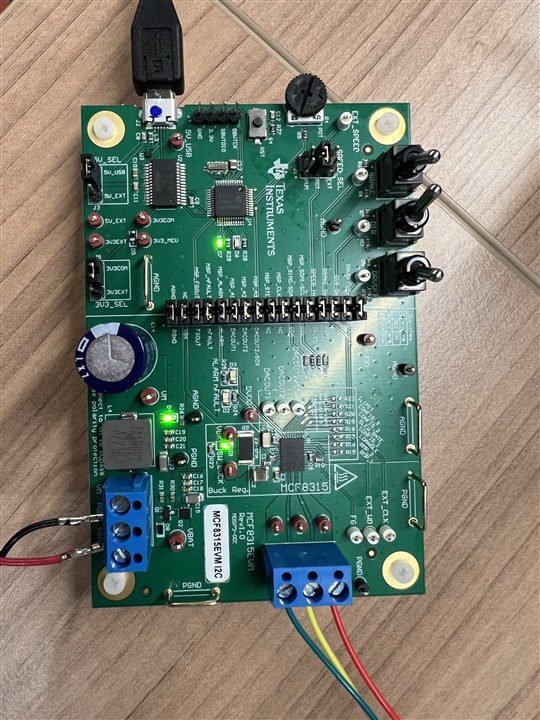

I'm trying to use the GUI guide MCF8315A_GUI version 1.0.1 with no success,

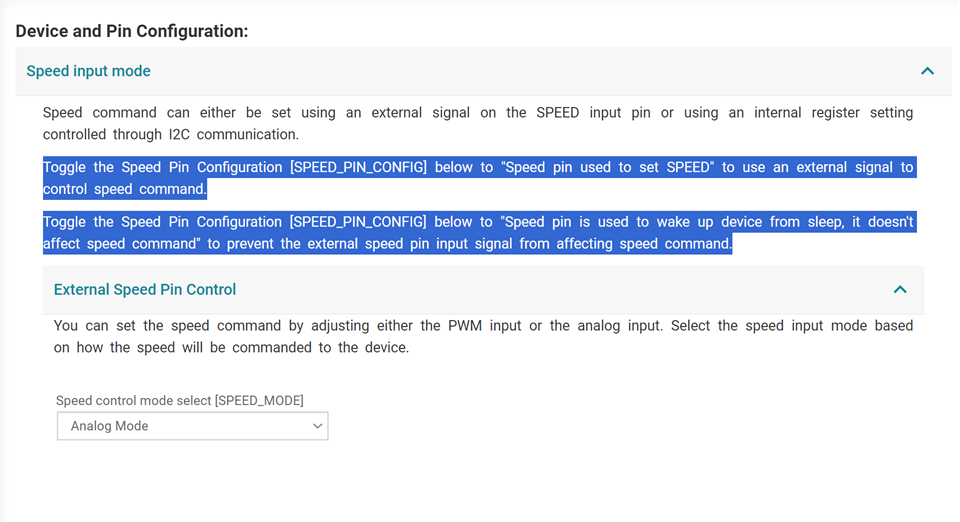

In the Device and Pin Configuration section I cant find the Toggle the Speed Pin Configuration [SPEED_PIN_CONFIG] below to "Speed pin used to set SPEED" & Toggle the Speed Pin Configuration [SPEED_PIN_CONFIG] below to "Speed pin is used to wake up device from sleep, it doesn't affect speed command"

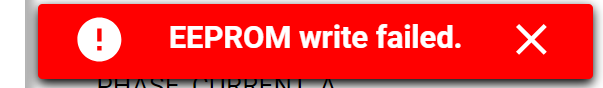

in addition the EEPROM actions does not work

I would like to get help, thanks!