Other Parts Discussed in Thread: BQ51050B

Hi TI team,

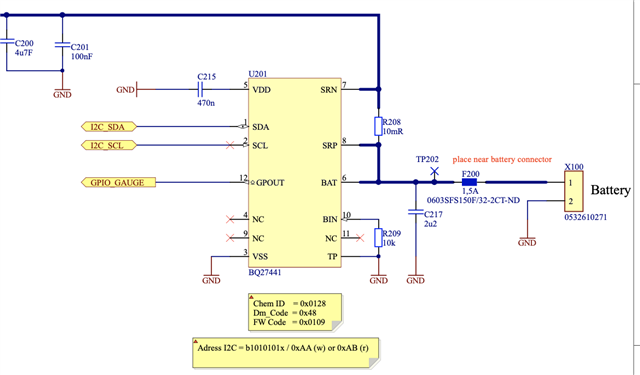

we have some strange problems with the battery fuel gauge.

With no change in our code we cannot communicate with the gauge over I2C.

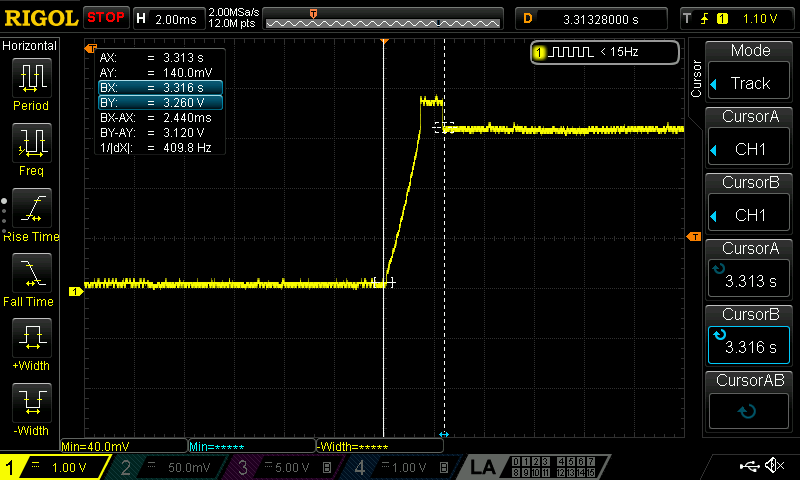

The Vdd of the gauge is at 1.8V.

I2C SCL and SDA lines are HIGH (but we also had a case where SCL or SDA were permanently low and Vdd at 0V).

Things we already tried, but didn't work:

- Resetting the comm engine by pulling down I2C SDA/SCL for 2s (even tried 3s and 4s) https://e2e.ti.com/support/power-management-group/power-management/f/power-management-forum/967941/bq27542-g1-fuel-gauge-holding-the-scl-line-to-low-and-i2c-bus-locked---working-only-by-doing-a-power-reset-that-is-not-possible-in-our-device

- Pulling GPOUT low for 1ms to try to wakeup gauge.

- Sending Reset and SoftReset commands over I2C

We were able to reproduce this state by performing the following steps:

- The attached battery is empty

- Attached our device to an QI charger (charger chip on our device: BQ51050B)

- Now the gauge won't respond to any i2c communication

The only way we can get the gauge to work again is by reattaching the battery as the gauge is powered over the battery, which is not a suitable workaround for us, because we have thousands of devices in field.

Thank you for your support in advance!

Thanks,

Clemens