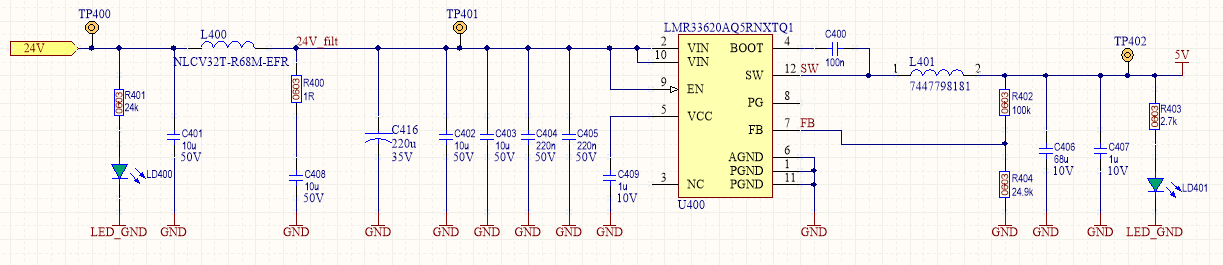

Other Parts Discussed in Thread: LMR33630

I had this issue on my prototype:

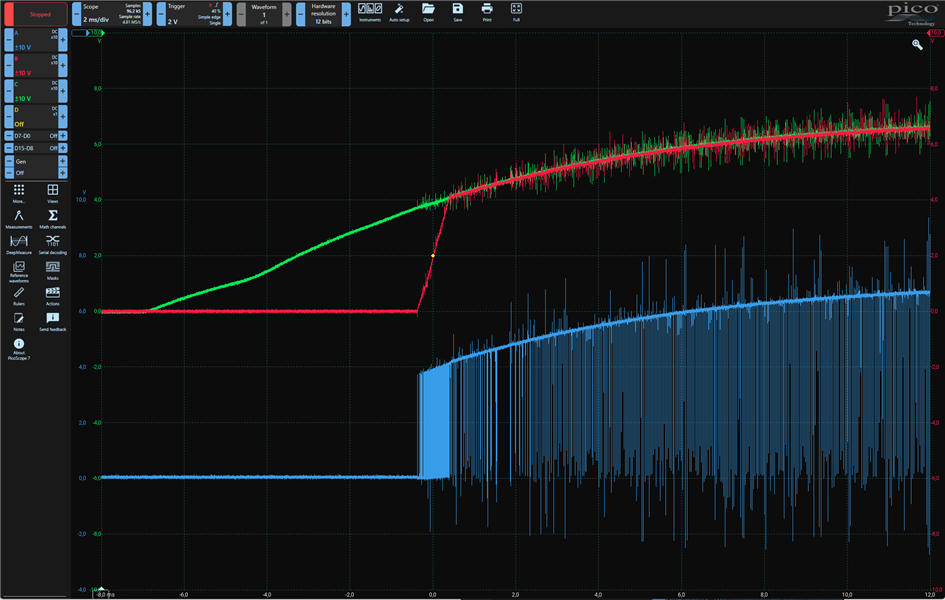

My LMR33620ARNX is switching at 140kHz with SW high 99.5% of the time. So Vout is close to Vin and FB is kept at 3V (when Vin=15V).

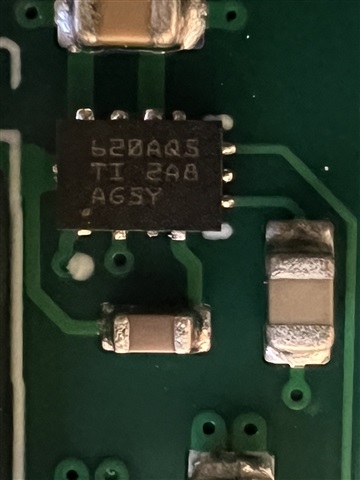

This was solved when I replaced the IC. But now I have got the production boards from the EMS and they all behave like the original prototype.

FB is not kept at 1V, I patched in a pull-up for PG and it is pulled low by the IC.

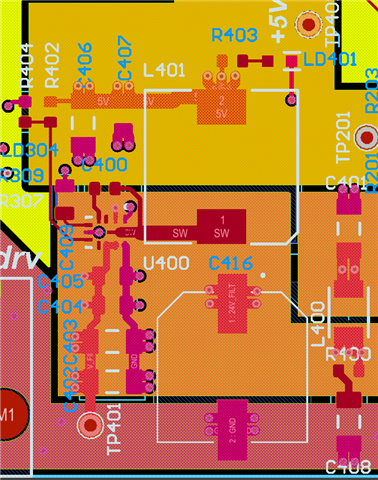

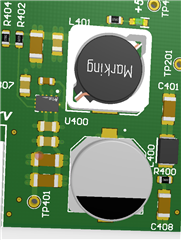

The layout is not according to the data sheet, but reasonably compact. GND plane (not shown) on layer 2, power polygons on layer 3.

I have verified the values of C400 and C409 and tried adding some capacitance directly at FB pin but it did not help . Any ideas or suggestions what to try next?