Hi all,

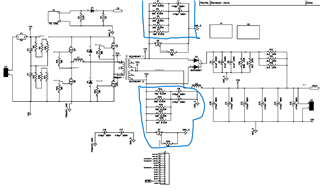

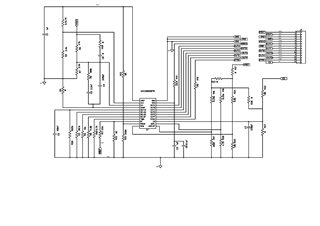

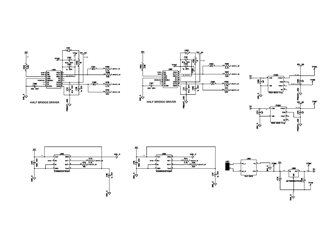

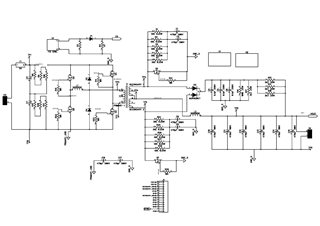

I trying to implement PSFB converter with UCC28950 IC. I am giving 12V bias separately and the input voltage(400V) through a Bridge Rectifier Circuit.

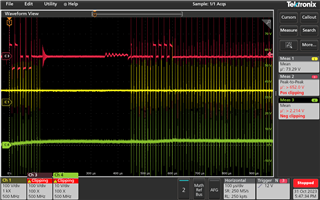

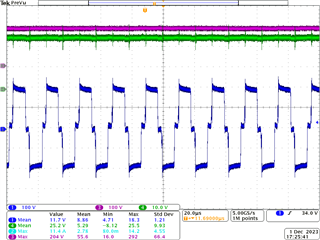

When the bias 12V is given, the QA, QB, QC, and QD are showing pulses of nearly 50% duty ratio. However there are no pulses for switching the secondary devices (QE, QF).

The Vref value is 5V, SS/EN is also 5V.

What could be the issue for the circuit not turning on.

What other parameters need to be checked for troubleshooting.

Thanks

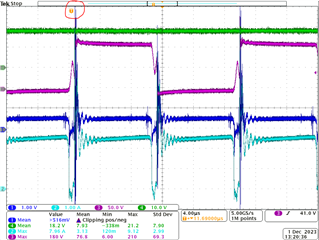

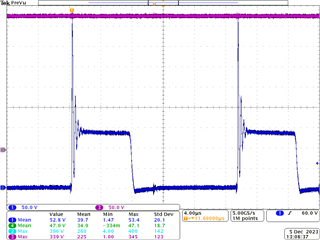

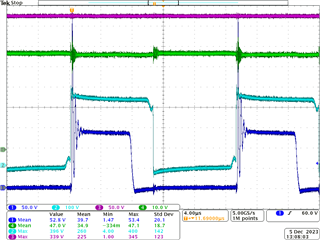

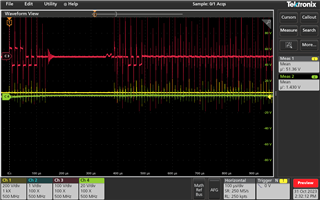

uously. After that it goes into some burst mode or some protection mode.

uously. After that it goes into some burst mode or some protection mode.