Other Parts Discussed in Thread: TPS40400, USB-TO-GPIO2,

Hello!

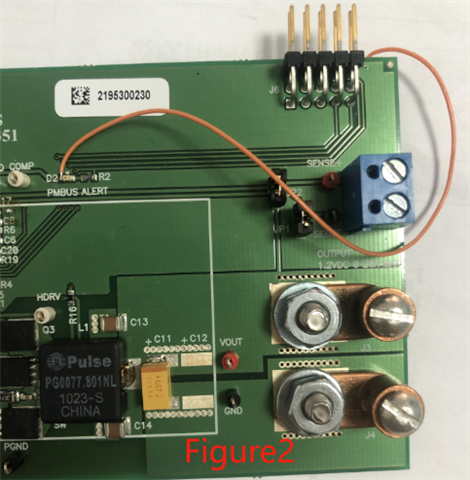

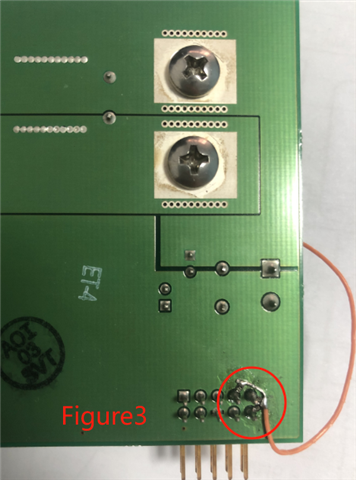

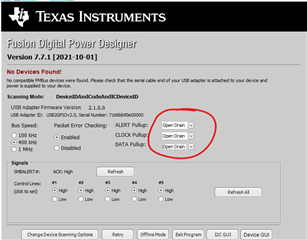

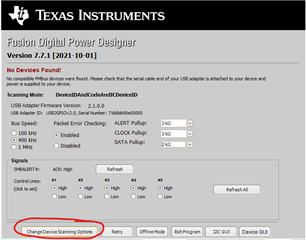

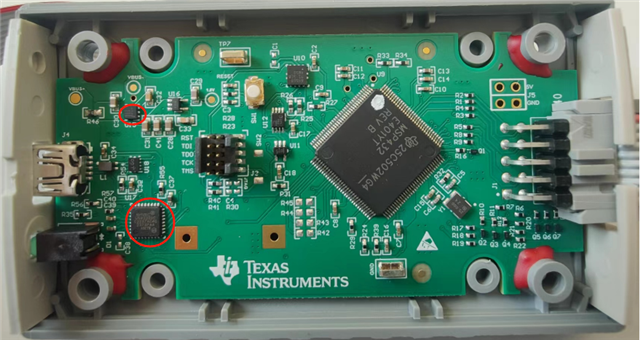

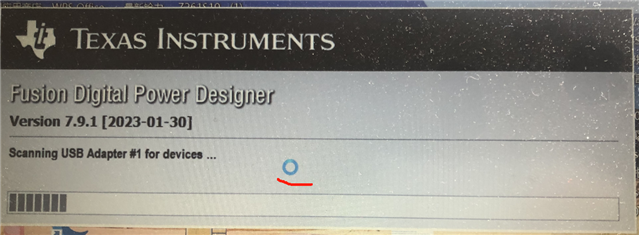

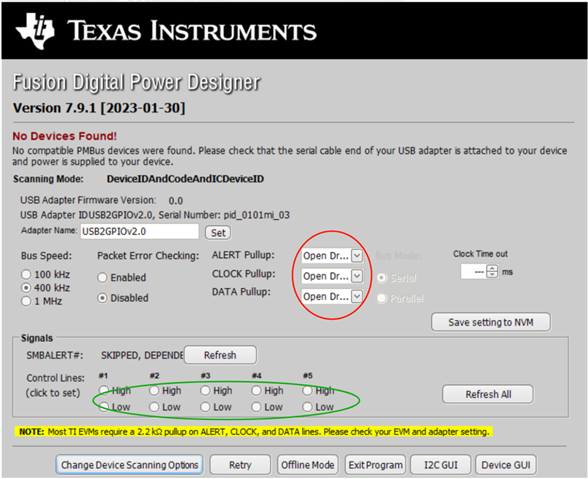

Connect the TPS40400ENM-351 test board and adapter as shown in Figure 1, at the same time, apply 5V power to the input of the test board, then connect the USB interface of the adapter to the computer, and open the Fusion GUI software, which can never recognize the TPS40400. If the voltage of about 3V is connected to three endpoints through 2.2KΩ resistors as shown in Figure 2 and Figure 3, the Fusion GUI software can recognize the TPS40400. Why is this?