Tool/software:

Hello,

I am working on designing a power supply with the TPS543C20A.

I will be using the TPS543C20A to step 14V Vin down to 1.35V Vout @ 25.5A Max Iout.

I don't have very many hard design parameters outside of that. I'd like a small enough ripple so that I don't see any switching artifacts on the output of the LDOs that the TPS543C20A will be providing the 1.35V to. These LDOS will be regulating the 1.35V to 1.2V.

As you can see by my provided information, I am by no means a power expert.

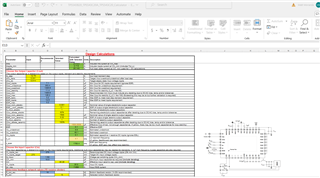

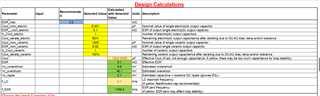

I've been working with the provided design calculator for the TPS543C20A.

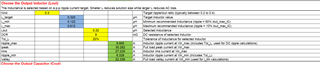

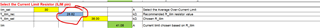

The first thing I've noticed is when I type in all of my parameters, the COUT values generated trigger a design caution:

It looks like the tool is warning about too much output capacitance causing loop instability.

I began with the provided value but the undershoot and overshoot vout cells went red. There doesn't seem to be a value that will turn the COUT cell green.

I was wondering if the TI team could sort of guide me through properly using the calculator as I don't have much(if any) design intuition on what the different values in the tool should be and am lacking most of the stricter requirement information that the tool allows you to design for and I would like to make sure I'm using sensible values at the least.

Any help that TI Engineers could provide would be greatly appreciated.

Thank you,

Matt

Thank you

Thank you