Other Parts Discussed in Thread: LM5177

Tool/software:

Dear all,

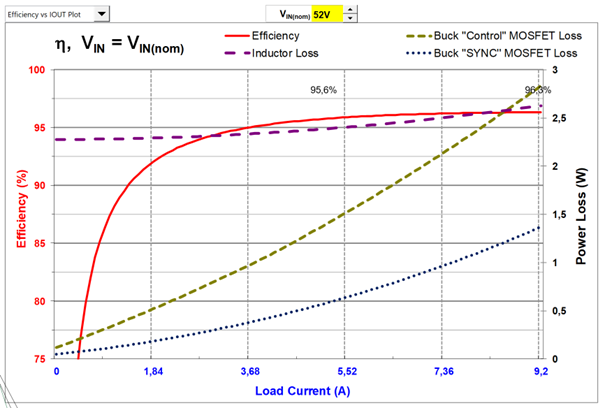

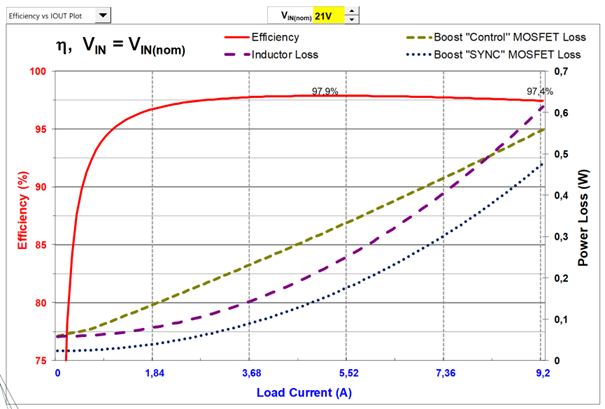

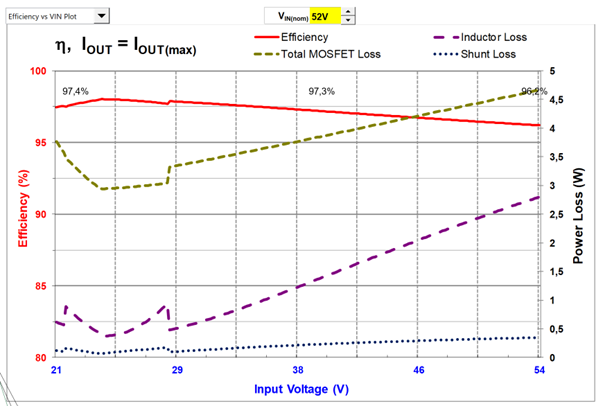

I'm designing a buck-boost converter using the LM5176. The input voltage ranges from 21V till 54V. The output voltage should be 24V (fixed). The maximum output current is 9.2A.

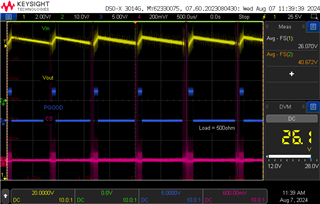

The converter seems to work fine when the input voltage is below 35V. However, when the input voltage reaches above 35V, the output voltage rises to about 26.5V and then the Output Overvoltage Protection (OVP) activates. As soon as the OVP activates, the voltage drops. When the voltage is low enough (when the OVP disactivates), the converter starts up again, and the steps above are repeated.

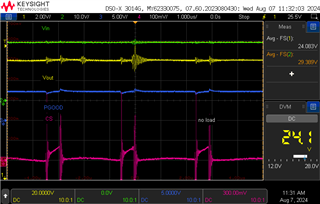

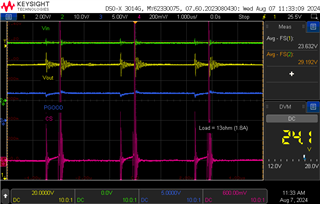

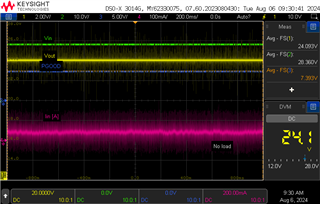

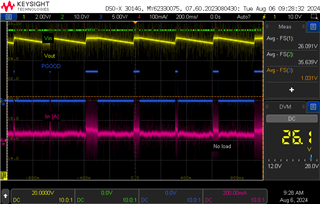

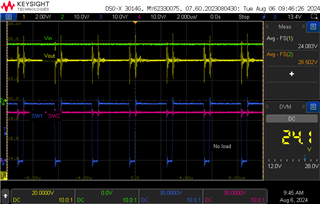

I have tried to capture some useful information. Please find some oscilloscope screenshots below.

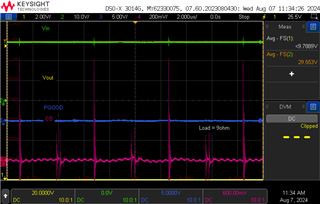

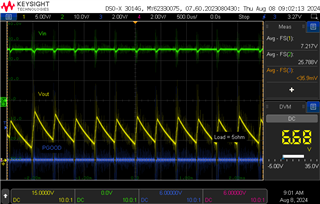

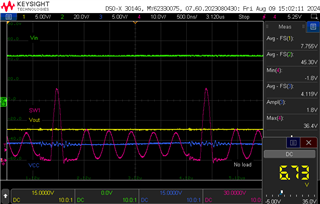

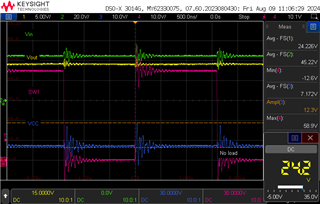

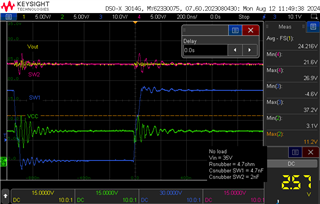

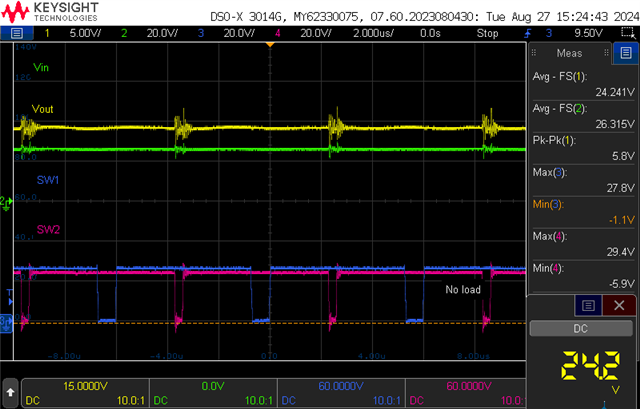

This first screenshot shows operation at an input voltage of 28V (green trace). The output voltage is 24V (as needed) (yellow trace). The PGOOD pin is pulled high (indicating that everything is fine) (blue trace). The input current is constantly about 20mA (pink trace). As explained above, the converter seems to work fine when the input voltage is below 35V (as shown in this screenshot).

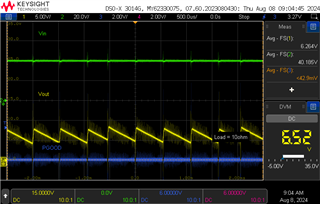

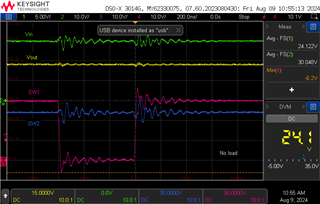

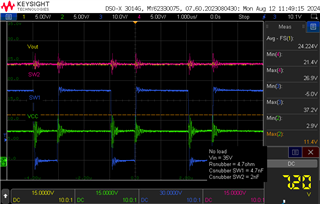

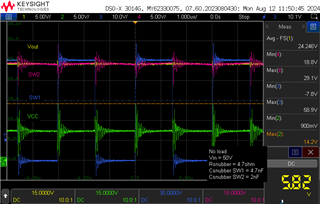

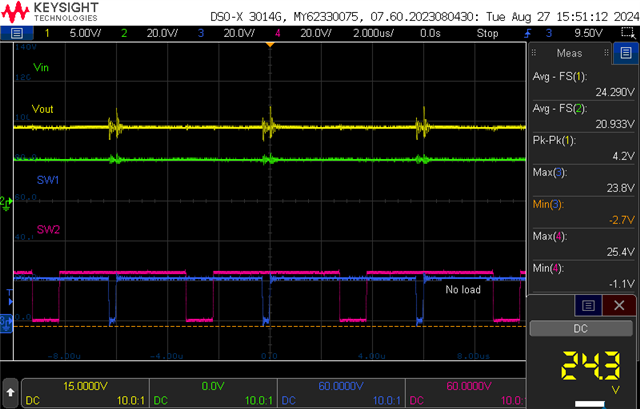

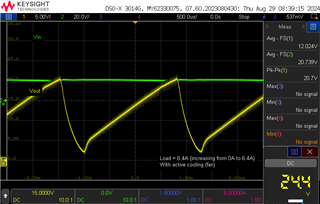

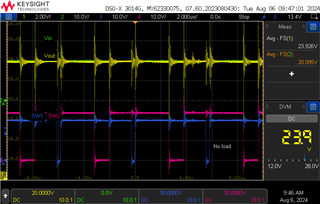

The second screenshot shows operation at an input voltage of 36V (green trace). The output voltage constantly switches between approximately 26.5V and 25.8V (yellow trace). The blue trace shows that the PGOOD pin indicates that converter only sometimes works fine. The pink trace indicates that the input current drops to 0A when the PGOOD pin is not high (indicating that the converter turned off due to OVP).

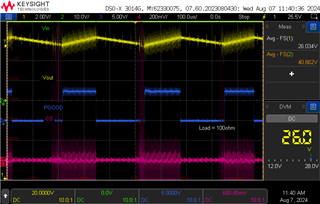

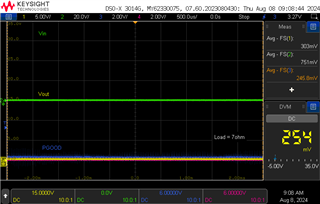

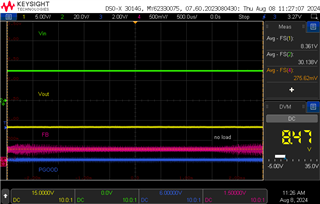

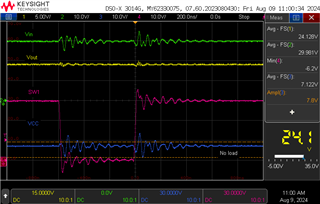

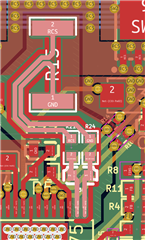

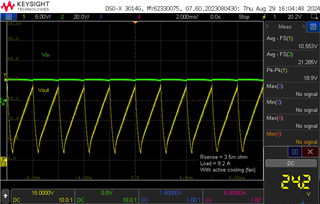

I also took two screenshots of SW1 and SW2 (the first one at buck-boost mode and the second one at buck mode). I’m not sure if this information is helpful for this problem.

Finally, I also took a video in which I increased the input voltage. You can see that at about 35V input voltage, the controller’s OVP activates.

Please be aware that all tests and screenshots above, are without any load.

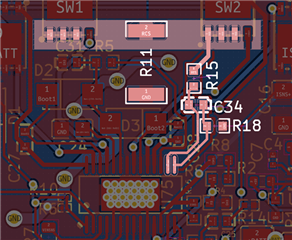

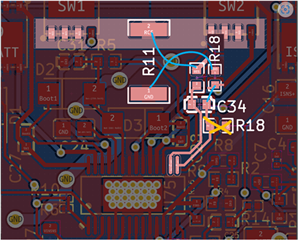

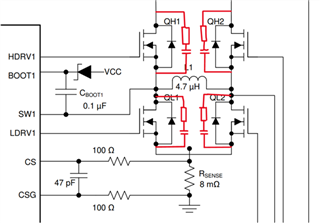

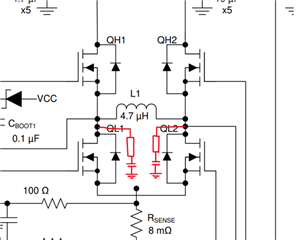

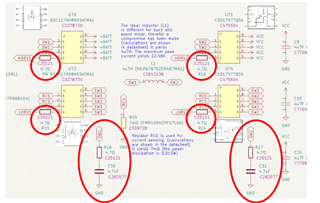

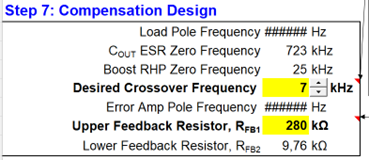

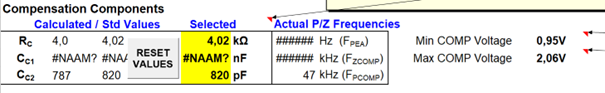

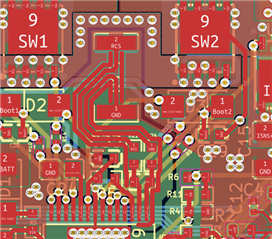

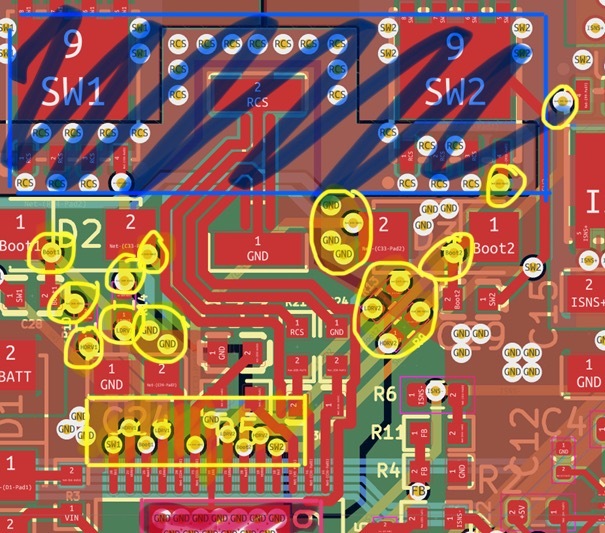

I designed my schematic using WEBENCH. This is the schematic:

I'm looking forward to your reply!

Best regards,

Max