Other Parts Discussed in Thread: LMZM23600

Tool/software:

The customer would like to design in the TPSM41625, but their factory automation team has some concerns/questions.

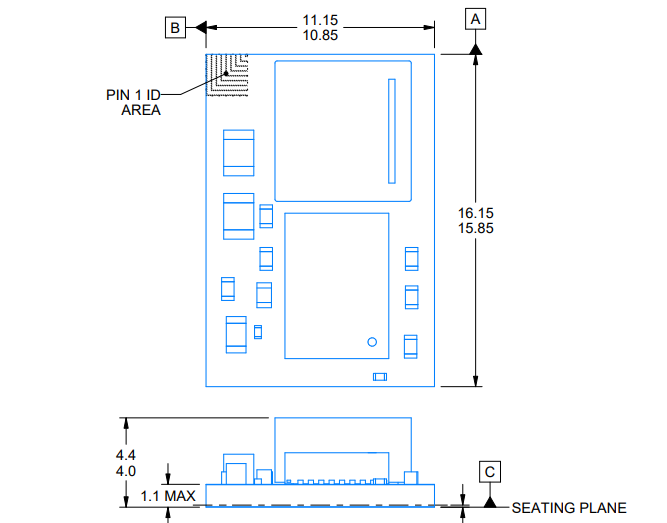

Can you please make recommendations on the best pick/place center of gravity for this device, per the customer: