Tool/software:

Hi, TI:

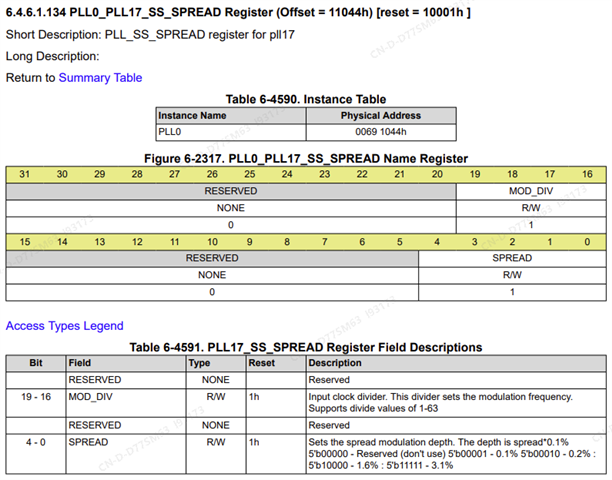

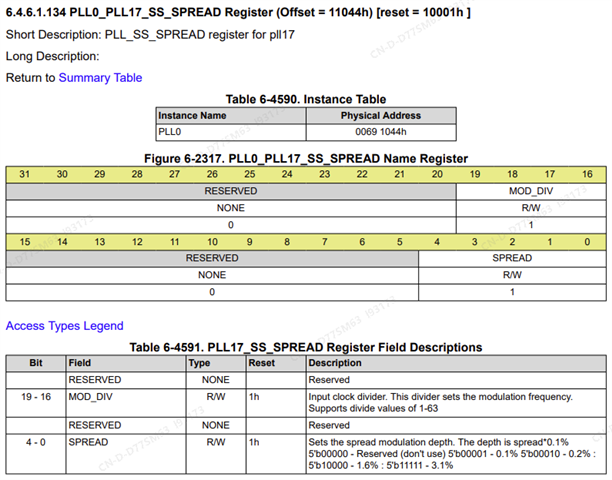

In the AM62x application design guide, the frequency division parameter setting for the spread spectrum frequency is 16-19 bits. Why is the parameter 1-63? How is this converted? I don't understand this part.

Tool/software:

Hi, TI:

In the AM62x application design guide, the frequency division parameter setting for the spread spectrum frequency is 16-19 bits. Why is the parameter 1-63? How is this converted? I don't understand this part.

Hi, Peaves:

But in the current test, we found that spread spectrum is useful, please refer to e2e.ti.com/.../am623-lcd_pclk-setting-and-emc-re-issues-for-dpi-interface-of-am62x-dss

I understand how this feature can be useful, but the SSC function in AM62x device was not validated as part of the initial device design. There has been some discussion to validate the function and some work has been done, but the effort has not been completed. That is why I said it is not currently supported.

It may be supported in the future, but we are not making any firm commitments if and when this feature will be supported. Therefore, we do not recommend using SSC until it has been validated and is officially supported.

Regards,

Paul

Hi, peaves:

If spread spectrum is not used now, the emission of LCD_PCLK clock signal is very strong. Do you have any way to reduce the strength of LCD_PCLK in AM623? We have no way at present. Adding magnetic beads and capacitors on the clock line is useless. For the problem of our product's EMC RE passing Class B, do you have any good solution?

Are you operating the IOs at 3.3V or 1.8V? Operating the signals at 3.3V will generate much higher emissions than operating at 1.8V.

The best option may be to place a serializer on the same PCB as the AM62x device and send video data across the cable via a low voltage serial data path that has lower emissions than multiple LVCMOS signals all toggling at the same time. Then use a de-serializer at the display panel to convert the serial data stream back to parallel data if the display panel requires parallel data.

The only other choice is to decrease loop area in your signal return currents by maintaining constant signal trace impedance for each signal as they propagate through connectors from one board to the next. You may also need to shield the emissions from the cable that connects the panel PCB to the AM62x PCB.

I do not have any other suggestions.

Regards,

Paul