Other Parts Discussed in Thread: TPS65219, TPS6521905, TPS65215, AM2434, TPS65220, AM6421, TPS22918, , TPS6522005-EP, , AM6548

Tool/software:

HI Board designers,

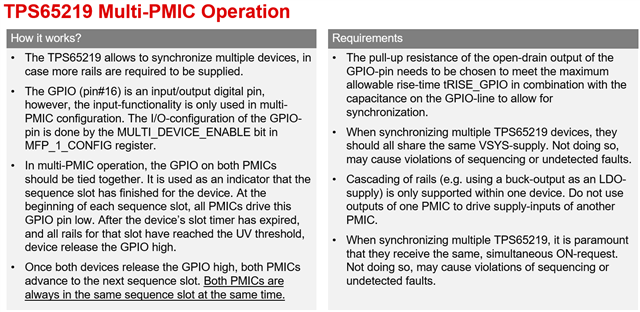

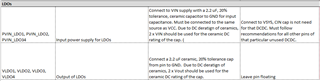

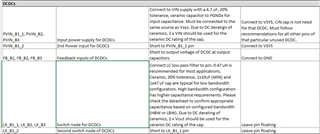

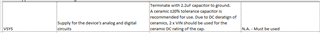

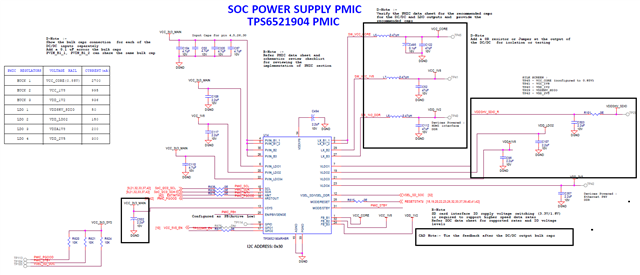

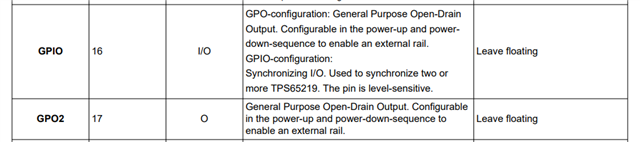

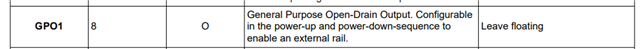

I am designing my board using TPS65219.

Are there some common recommendation or observations that i should be aware?