Hi,

we are using capacitive touch sensor for our application.

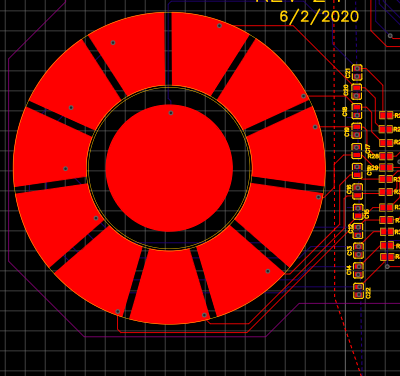

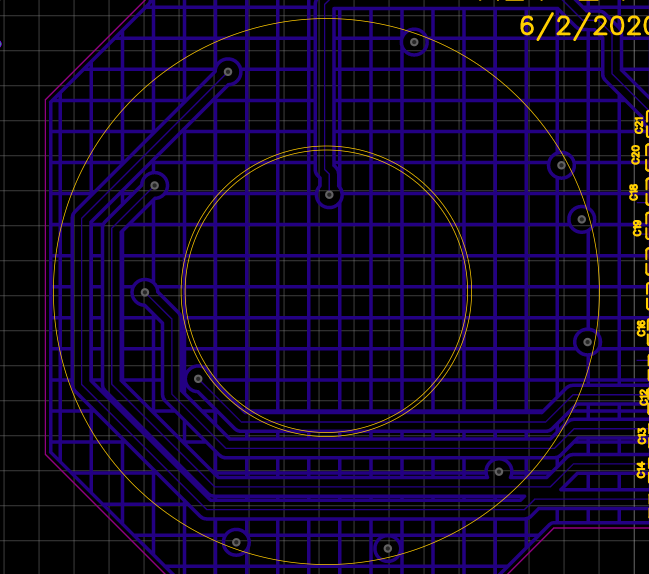

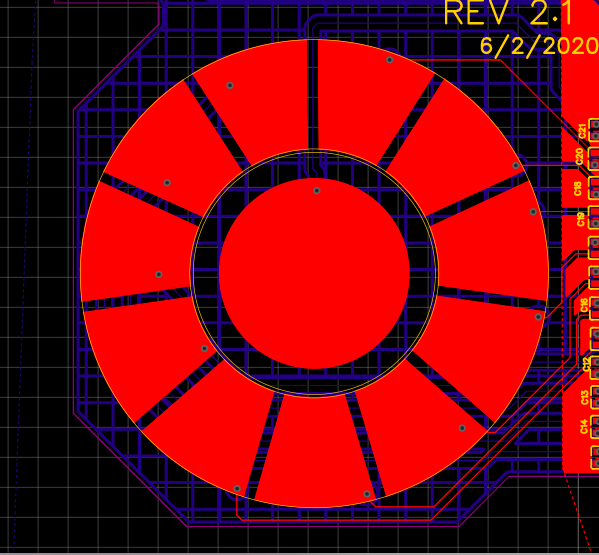

The design is attached below

The capacitive touch sensor has a 2.5 mm thick ABS sheet above the touch sensor.

Could you please suggest any capacitive touch sensor IC's ?

The dimensions of the design are

- the diameter of inner circle ( button) is 16mm

- The spacing between capacitive pads are 0.9 mm

- length of the pads 9.27mm

- area of each pad is 70.84 mm2

Thank-you

Warm Regards

Harini Krishna