Other Parts Discussed in Thread: AFE030, AFE032

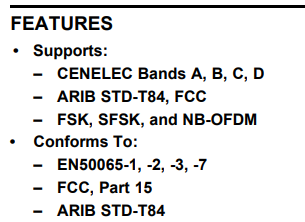

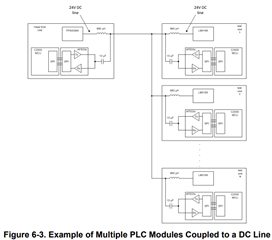

dear forum: I am working on a NB-PLC modem project using AFE031 in the CANELEC B band (95-125 kHz), that has the potential to become a commercial product for sale in the US market, and so it will therefore require FCC Part 15 (conducted/radiated).

My question:

1. if I make the design compliant to CANELEC B, will it also be compliant to FCC part 15 (i.e., will it pass FCC since it is within the FCC allowed 9-490kHz band)?

2. will there be any special considerations to be taken to have it pass FCC?

thanks

Alex