Other Parts Discussed in Thread: OPA330

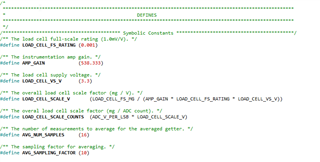

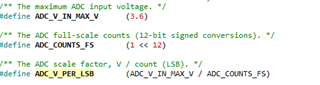

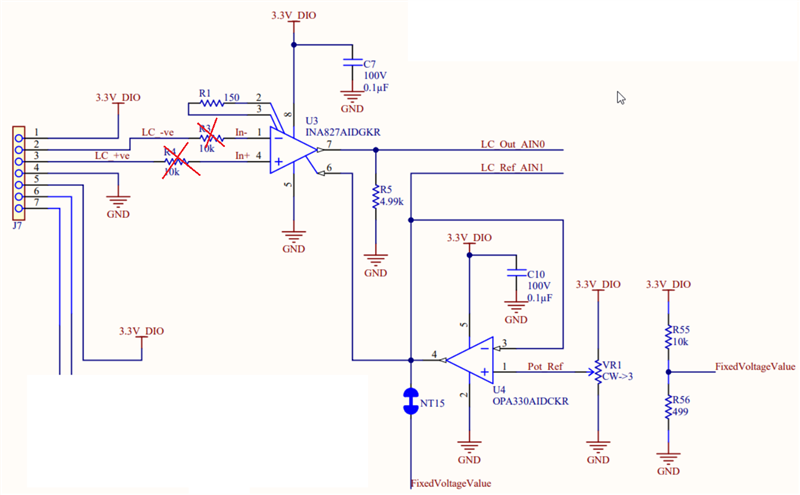

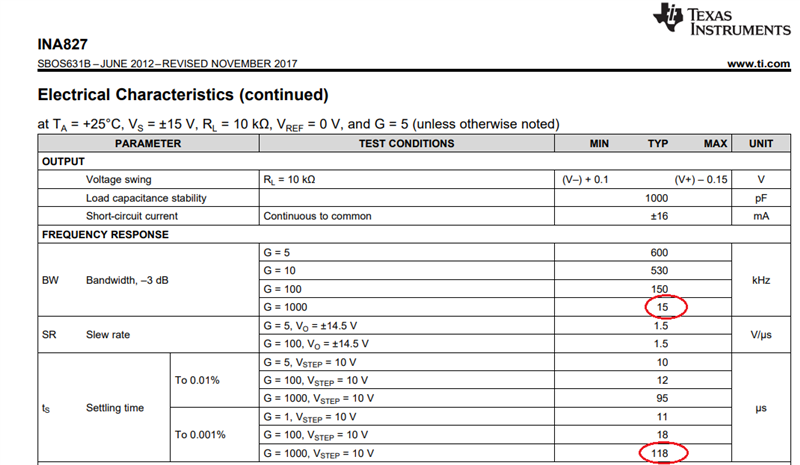

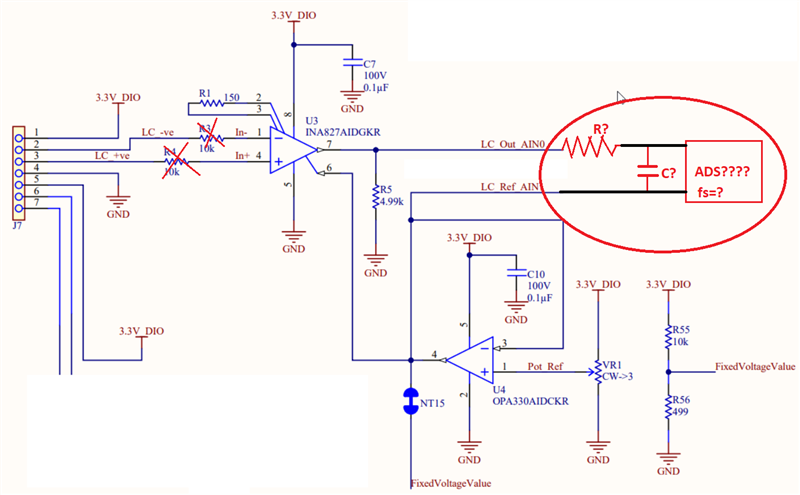

I am using the INA827 to drive a 5kg FMZK loadcell. And despite thinking we have the equations calculated correctly and our resistors set etc we are not seeing an accurate reading on the loadcell. Our loadcell readings are about 15-20% below what our known weight values are and we have + or - 10g variance as well.. I am attaching the schematic from our PCB to this post and the C code we we are using in conjunciton. Any help is greatly appreciated as this is really stalling our project ATM .