Other Parts Discussed in Thread: PGA308, , XTR116, PGA309

Tool/software:

Hello,

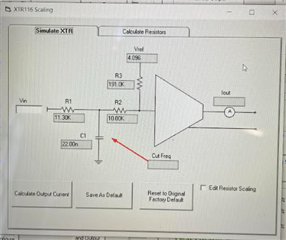

I am looking for help verifying connections for the "one wire" calibration method. For the attached circuit (figure 6-3 of PGA308 manual), I don't see any explicit guidance in the manuals and would like to verify the following hardware connections/settings for writing calibration gains to the PGA308.

T4 (Vout_F) to "one wire or Riso of circuit.

T4 (ground) to Iret of circuit.

T1 (Vref Ext) to 4-20 high of circuit.

T1 (Ground) to 4-20 low of circuit.