Other Parts Discussed in Thread: TINA-TI, , TIDA-00909, INA219, INA282, INA181

Hi,

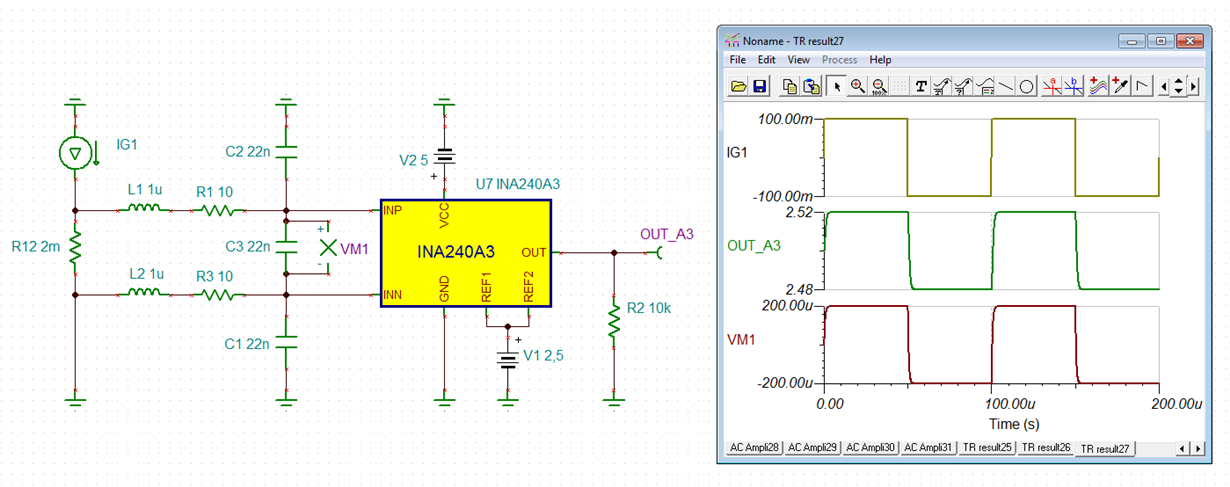

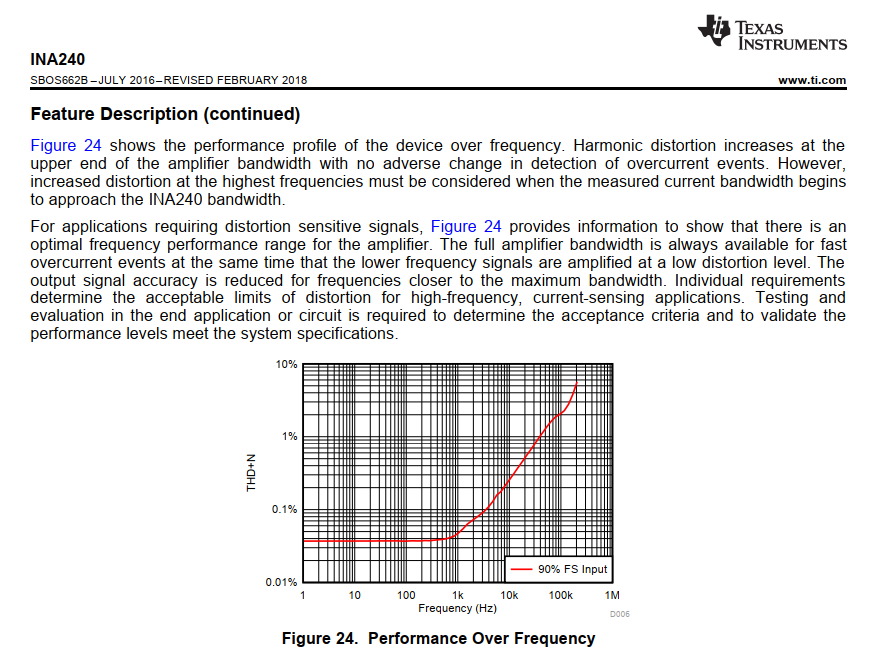

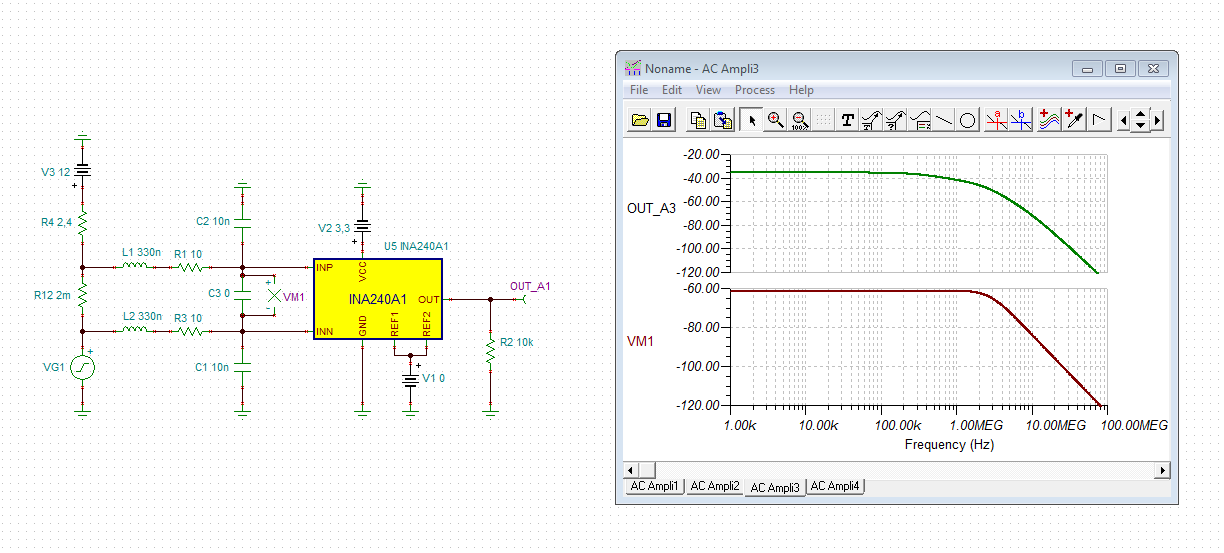

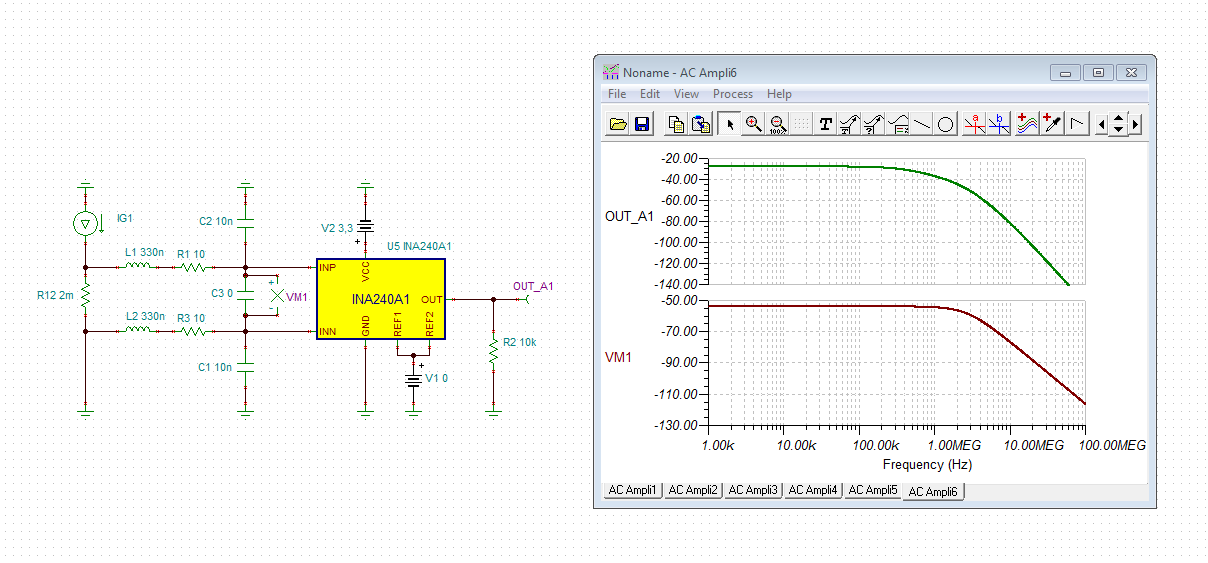

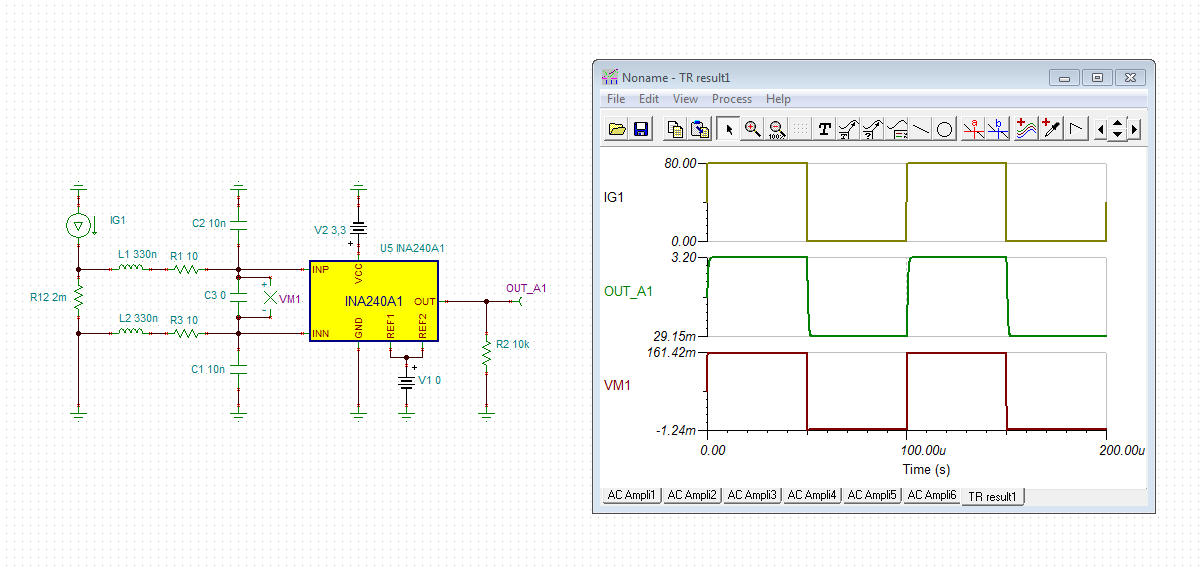

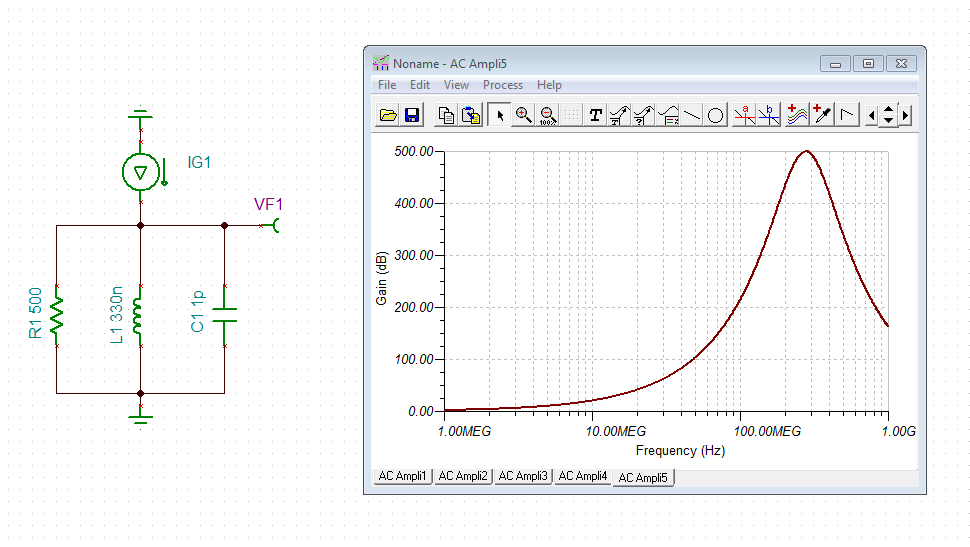

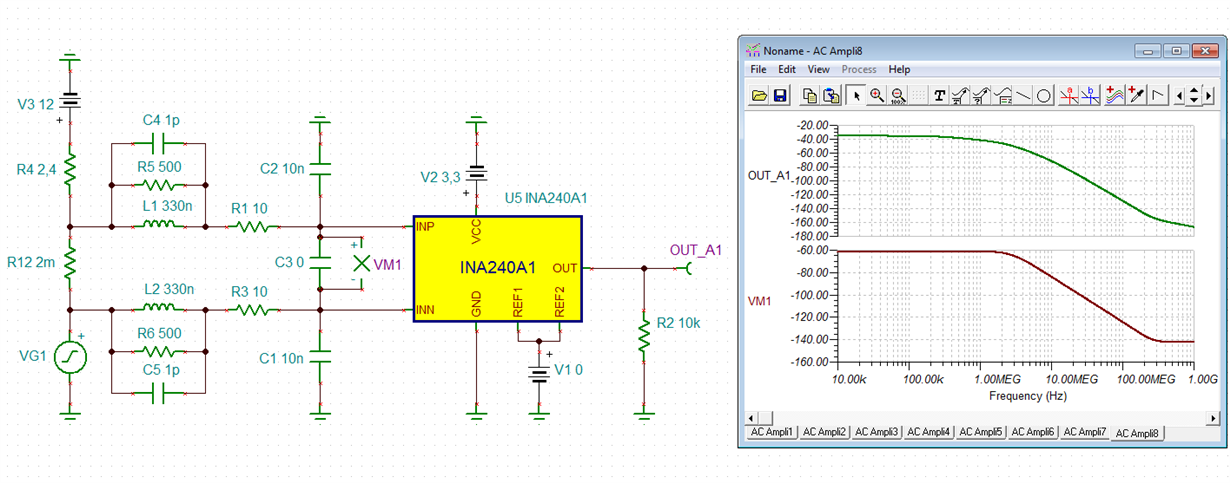

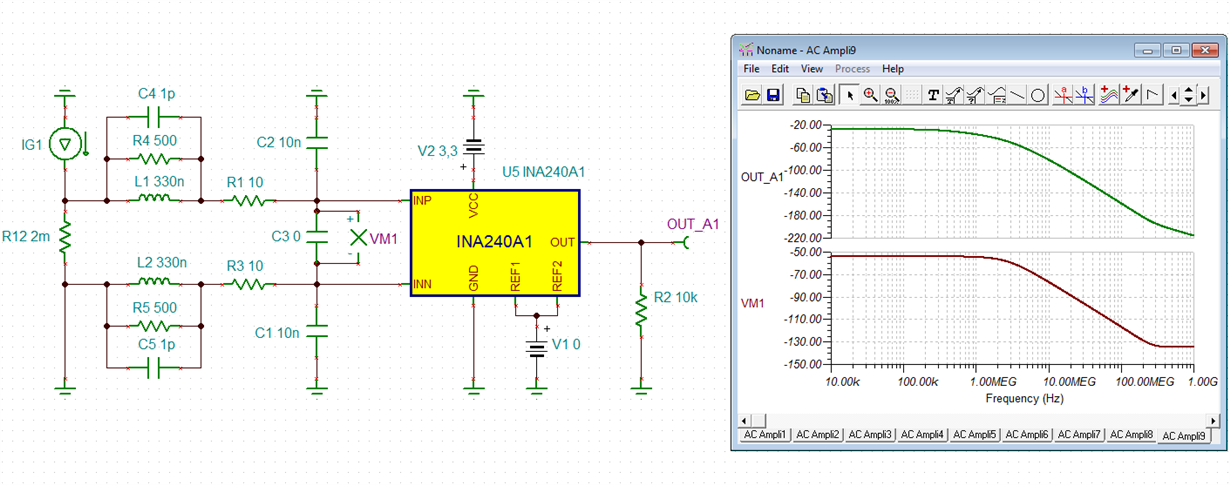

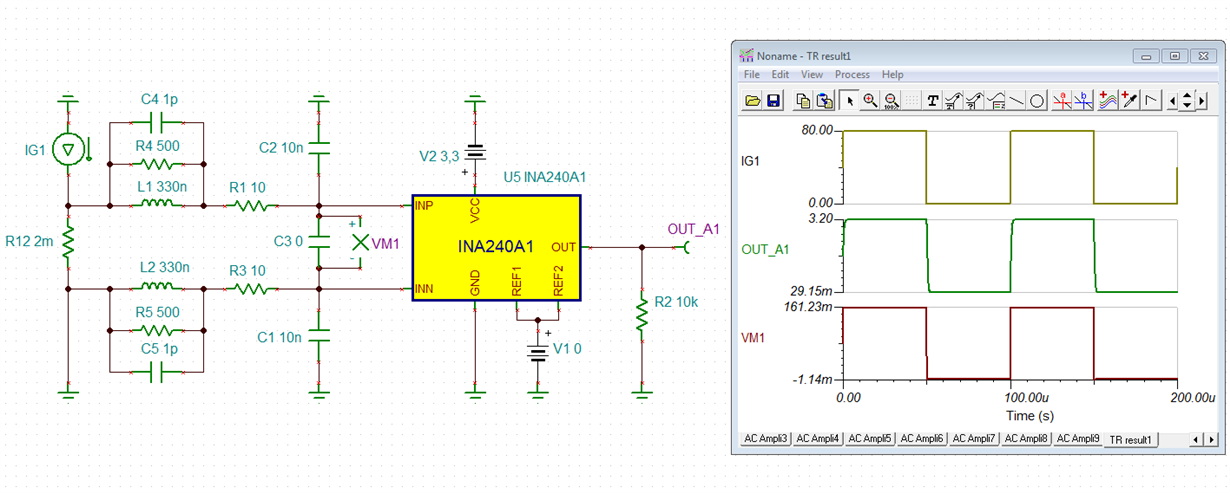

What is best way to stop high frequency 20-60mHz low side shunt EMI transients persistently passing to INA output? Is that even possible to expect from a shunt connect into differential amplifier without TI proprietary signal isolation being present?

Note INA monitors same phases of DC drive signal into motor which are EMI free. So EMI (dV/dt) originates near or below ground and is not being PSRR rejected on +/-IN @-60db thus passes into output. The 3 motor drive signals are free of this EMI signal, not dI/dV/dt. Yet the INA output is plagued by high frequency amplitude pulsed EMI wave forms passing into MCU. That is effecting several MCU peripherals behavior especially SAR ADC acquisition settling time distorts conversion >400us.

INA alone simply is not stopping EMI transients no matter how or where scope probe connected to INA output on PCB, it is real trouble.