Other Parts Discussed in Thread: TIPD188

Good DAY.

I need some help with an old project that i found on your site.

I want to build a micro gram scale. The hardware is not a big problem, but i need to know where i can get the code for the micro controller.

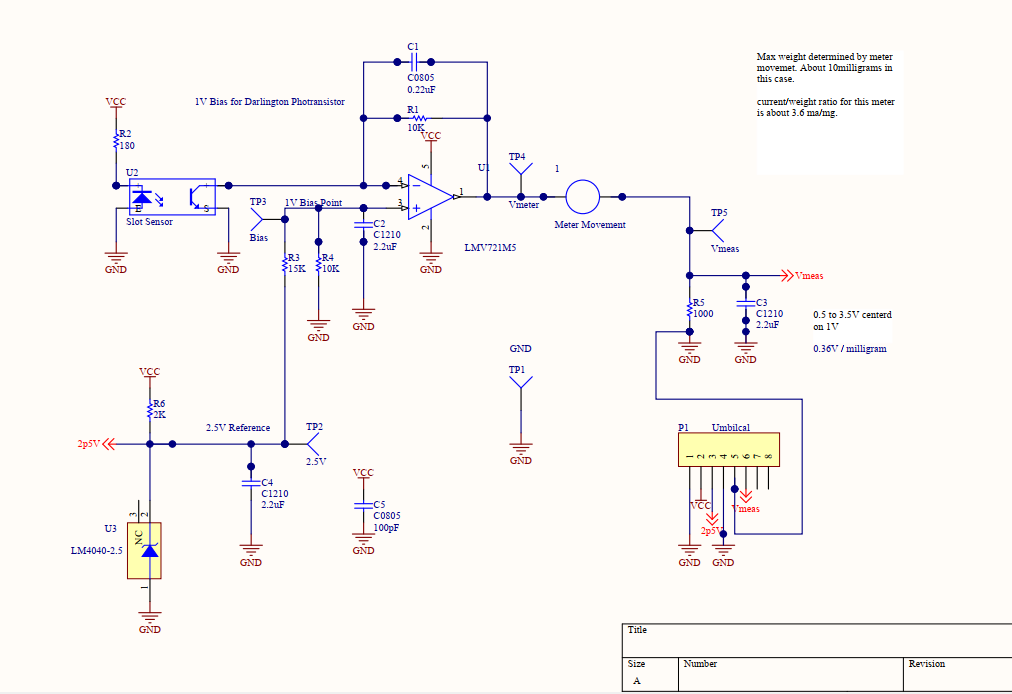

I also would like to know if the power supply that drives the electronics for the panel meter is a +5 0 -5 volt supply. I found the meter control circuit on this site but no circuit for how to connect micro controller and LCD to meter circuit.

Thank you.

Christiaan.