Tool/software:

Hello TI experts

SDK : motor_control_sdk_am243x_09_02_00_09

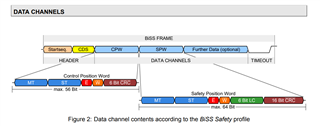

I noticed the support for BiSS safety is now available on the sdk above. I am having problem to configure BiSS to communicate to BiSS Safety encoder from Renishaw.

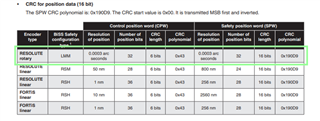

I am trying to communicate with Resolute rotary encoder as per the table below. Would you be able to provide guidance on the configuration steps to communicate with Resolute rotary encoder.

Thanks

Attached is full Data sheet

L-9517-9884-02-B_Data_sheet_BiSS_Safety_RESOLUTE_FORTiS_EN_TI.pdf

Alan I