Other Parts Discussed in Thread: OPA354, , OPA356

Hello,

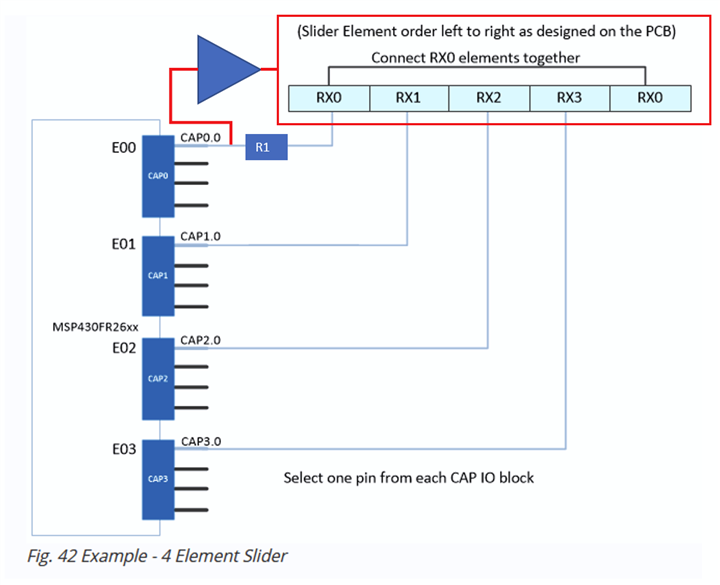

I am working on a project that requires a circular slider with a total circumference of nearly 1m. The biggest issue this is parasitic capacitance on this design. For this reason another engineer choose to utilize multiple MSP devices to break the slider up into 5 ~250mm long sliders. Each is controlled by a single MSP. While this reduces parasitic capacitance, it results in 5 different MSPs all operating out of sync. I see two paths forward here:

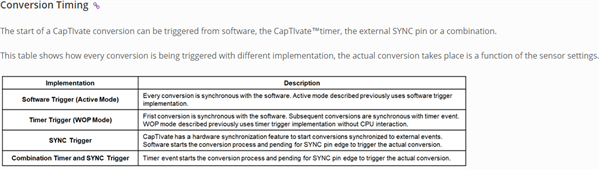

1. Synchronize all MSPs of a single external XTAL, and provide a sync signal between all MSPs. This would allow us to implement TDM where each MSP samples their given touch slider during separate time slots. Is this feasible or advisable? If all MSPs are synchronous could all MSPs scan during the same synchronous time slot?

2. Switch to using a single MSP with 16ch assigned to 4 slider elements. The max trace length could be up to 500mm long. The parasitic capacitance of this would be massive, and we would pick up significantly more LED PWM noise.

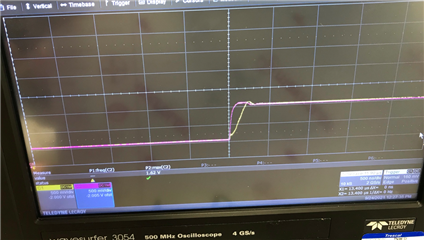

I am also interested in implementing a driven shield under each slider. Currently we are using self capacitance, so I would utilize the OPA354 to drive a hatch plane under slider element. The OPA354 would be connected to CAP0.0 before the series resistor feeding the RX0. Would you please confirm if this is the correct implementation?

Would it be beneficial to tap off CAP2.0, as it has the shortest trace length and lowest parasitic capacitance instead of CAP0.0 that has the longest trace length and greatest parasitic capacitance?

Please let me know if we are barking mad. . .