Similar to these previous threads:

We're using the DRV8350 in a BLDC drive application and experiencing driver chip failures. The chip works for some time in our application and then will fail with only the "Fault" bit (bit 10) set and will consume some extra current (~100mA) while it is enabled. We've set the gate drive currents low and observe no ringing on either rising or falling edges of high or low sides. As far as I can see our application schematic matches the various reference designs.

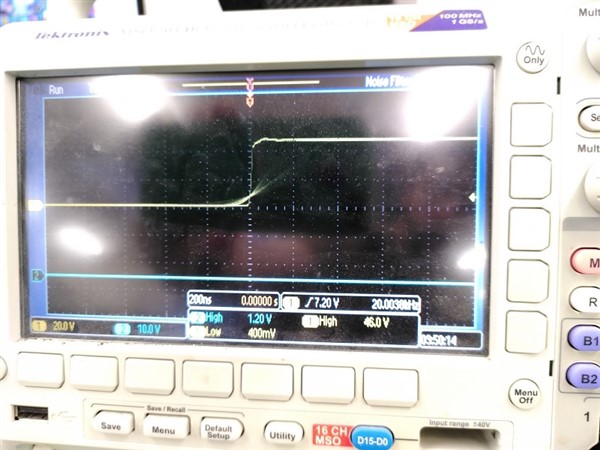

Failures seem to occur when there is significant regenerative energy produced from the system, however we've made extensive measurements of the power rails and see no spikes beyond 55V which should be well within the specs of this chip. We're using a fast comparator and large power resistor because our power supply cannot sink current.