Other Parts Discussed in Thread: BQ40Z50, GPCRB,

Dear TI experts,

as described in the older forum posts, we had some discussions about using the internal temperature source or external on and one the other hand we had problems with jumps in the SOC at low temperatures:

In one of our lasts tests we had six batteries programmed with the same .dfi file and then on three we set TEMP1, TEMP0 = 0,0 = Internal Temperature Sensor and on the other three we left TEMP1, TEMP0 = 1,1 = Average of TS1 and TS2 Inputs. Then all batteries were fully charged at room temperature and then two of each type were installed into the application (inside the climate chamber) and the remaining one was set into the climate chamber without application, so they were not charged or discharged at this time. Then the climate chamber was set to -20°C and the setup was left running over the weekend.

One Monday the tow applications with batteries with the internal sensor where running, so everything was fine and the two applications with the batteries with the external sensor were shut down, so the SOC had jumped to 0%. Then to verify the result we took the two batteries out of the application and put the two batteries into the application which had just set in the climate chamber without charging / discharging and the applications started again working. After letting the setup run for additional 10h the application with the applications with the batteries with the external sensor shut down. Again, this was caused by the battery reporting SOC = 0% to the application.

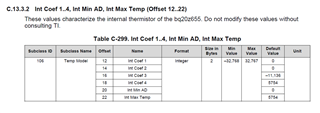

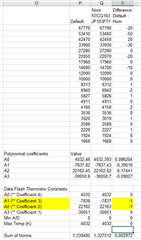

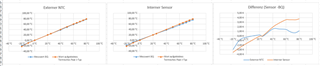

In an older test we also compared the internal and external temperature measurements with the reading of a type-J-temperature probe which was glued close to the BQ where the error didn’t seem to be too big:

To summarize our question, is there any explanation which different influence the internal or external temperature source has on the fuel gauging?

Yours Tobias